How should the hand test be done? How much detail do we need in the EL photo? We were puzzled by many questions, such as, if we can take a photo to see what details we can see, we can see whether it complies with the quality guidelines in panel production.

The EL test journey also brought with it a lot of trial, error and learning.

In order to take an EL photo, you first need to know what EL is. EL is not just a photo you can take with equipment; you need to turn a solar panel into an electroluminescence (EL) source. In other words, we energize the solar panel and turn it into a UFO heater. “What do you mean?” I can hear you ask. Yes, we light the solar panel like a lamp to take this photo.

Since the photo is a long exposure, you apply this voltage for about 10 seconds, so nothing happens to the panel, but if you apply it for a long time during the test phase, you will burn the panel. Don’t try it yourself at home 🙂

After learning the technology thoroughly, we built our own small test station and started our first trials.

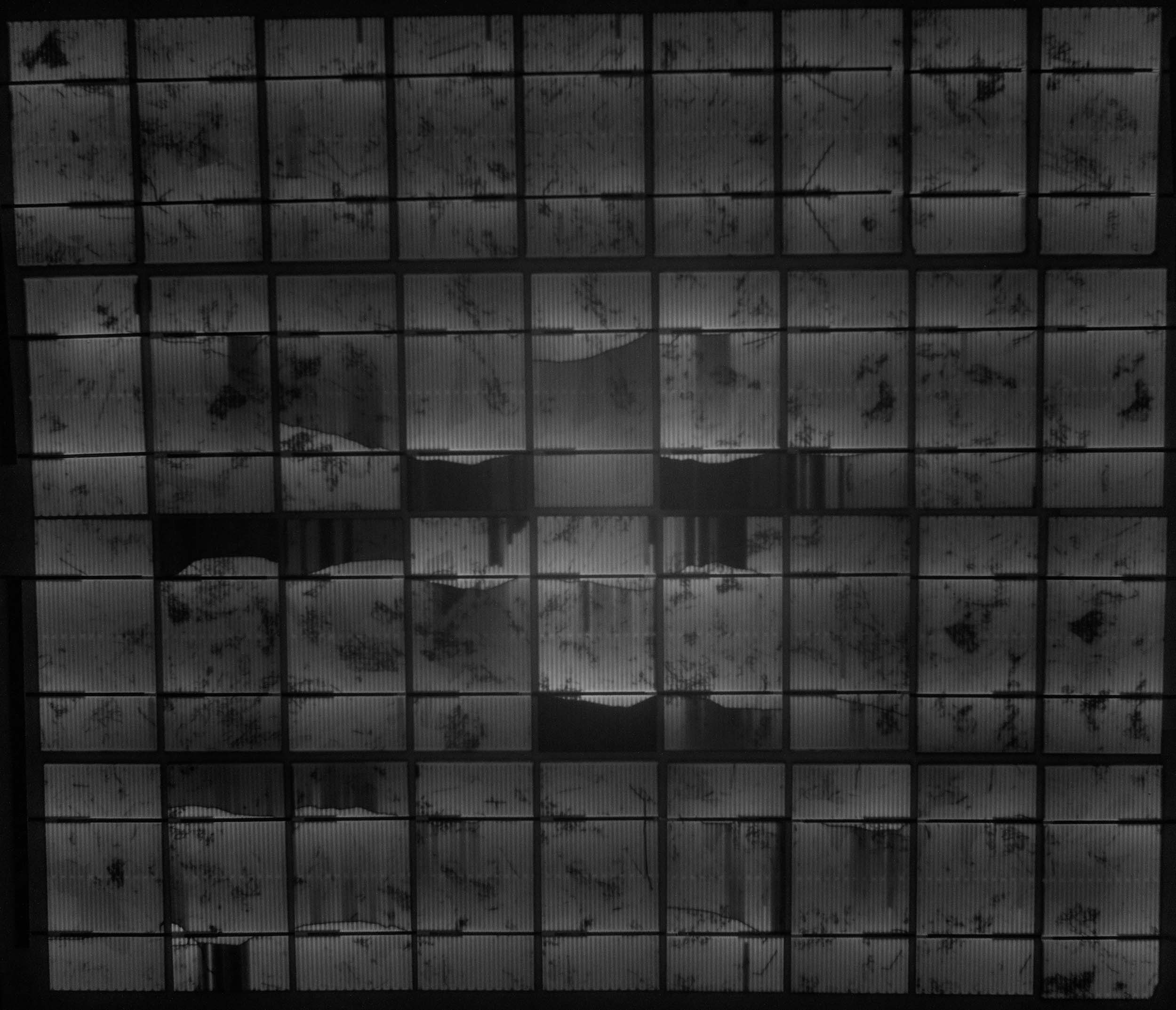

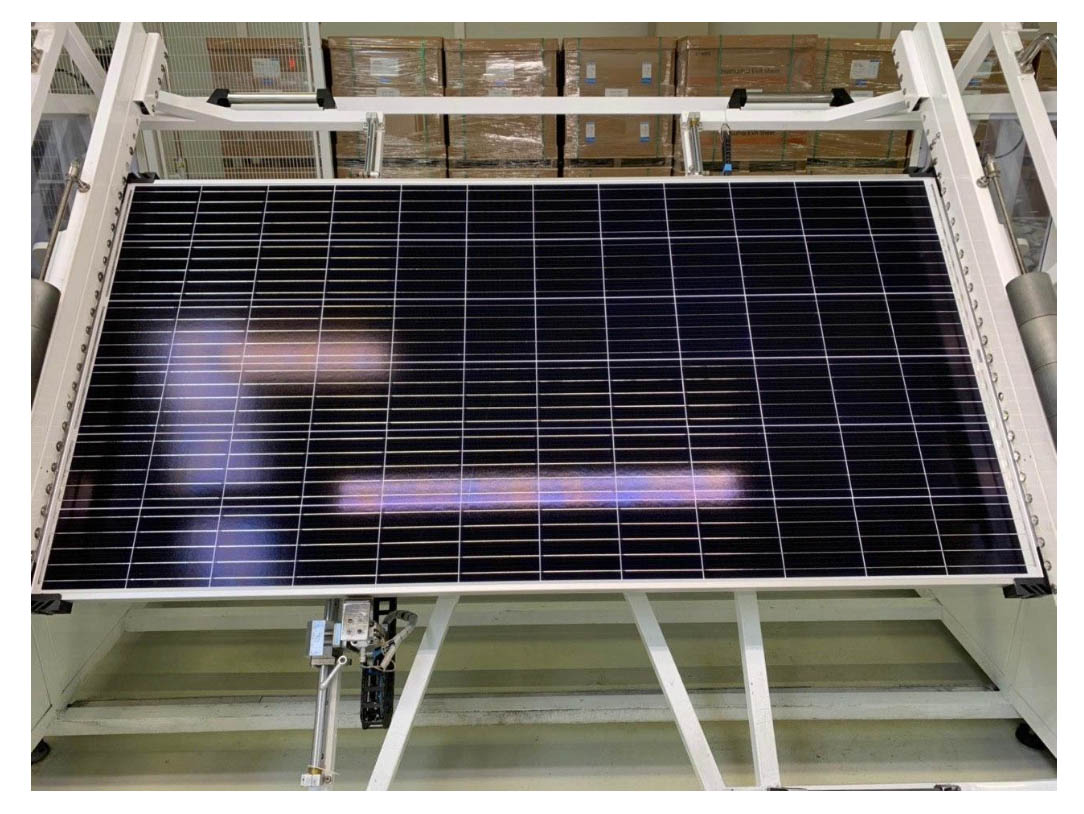

Even though this EL photo was not clear and did not have enough pixel detail, it was an indication that we were on the right step. We immediately went to the field and made our first test.

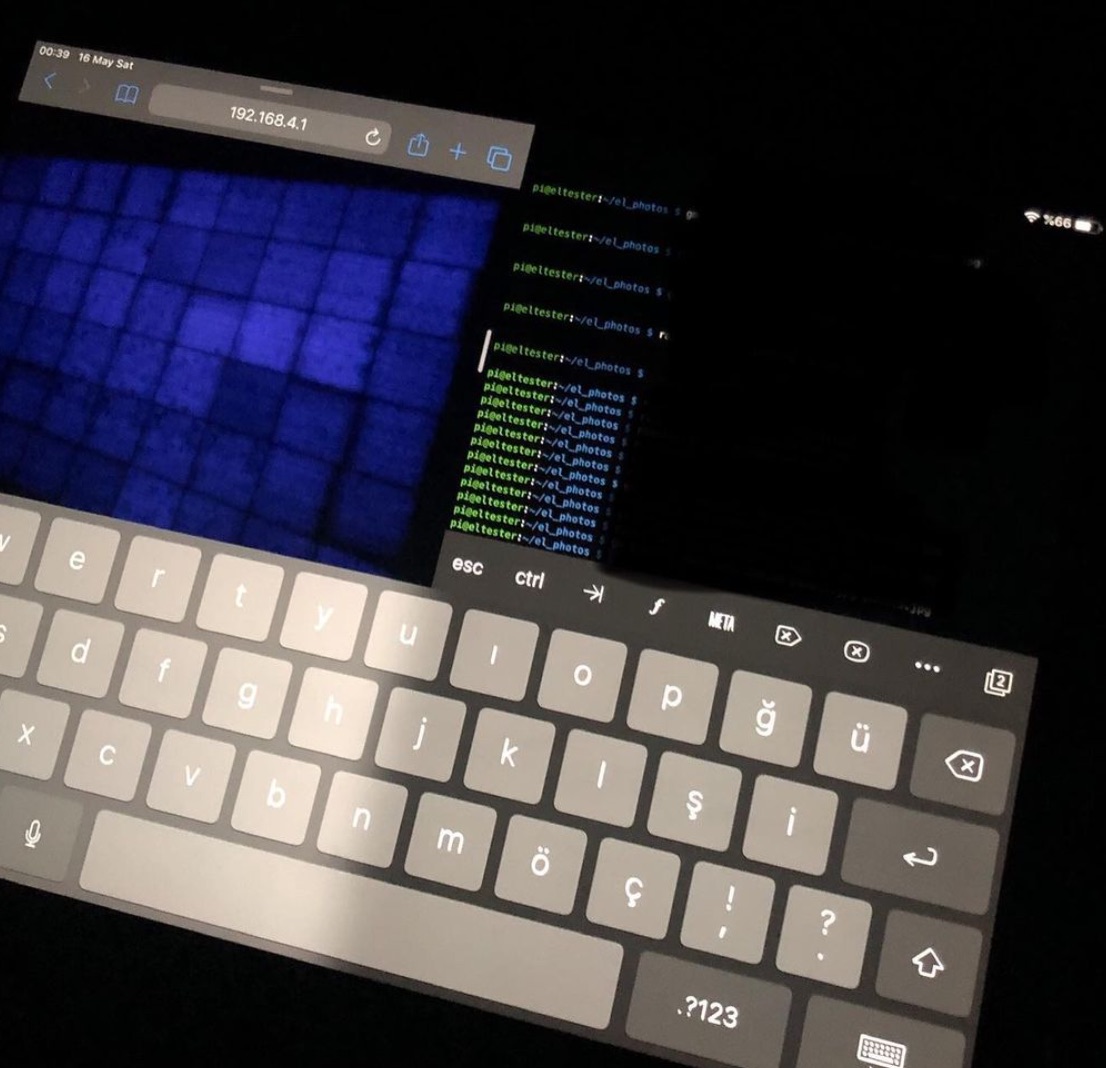

One night we conducted our first experiments at the facility of a company where we regularly carry out O&M processes. The goal was to use RaspberryPi to push files to the cloud and process them there.

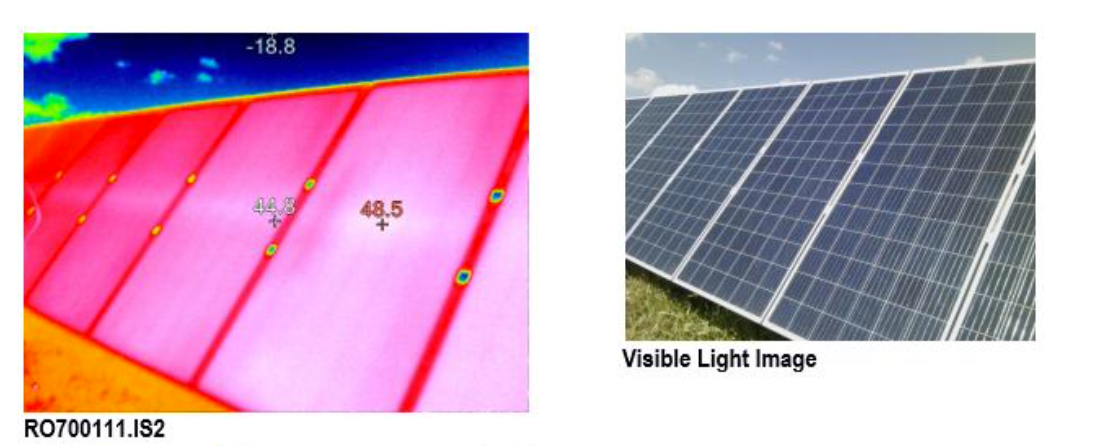

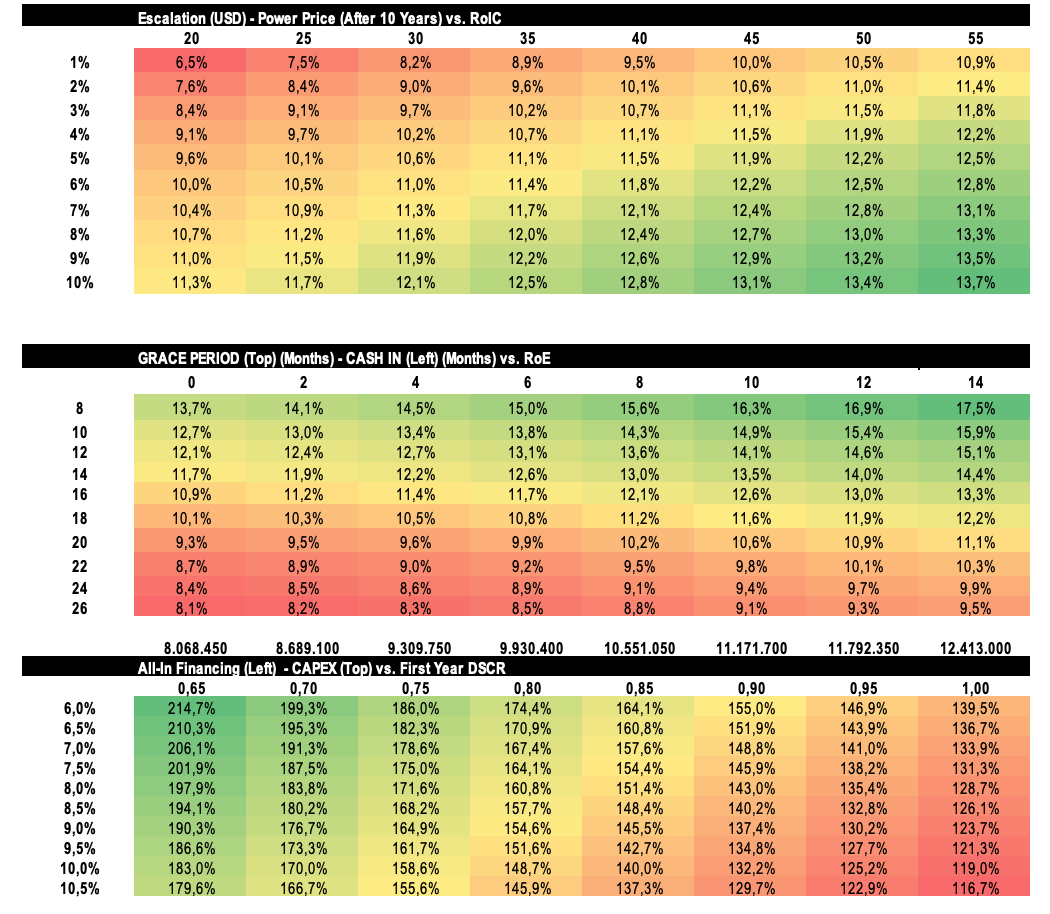

At this stage, communication and machine learning technologies were ready to be used. The infrastructure was there, but the images were not of high enough quality. So how do we define quality? How high quality should an EL photo be?

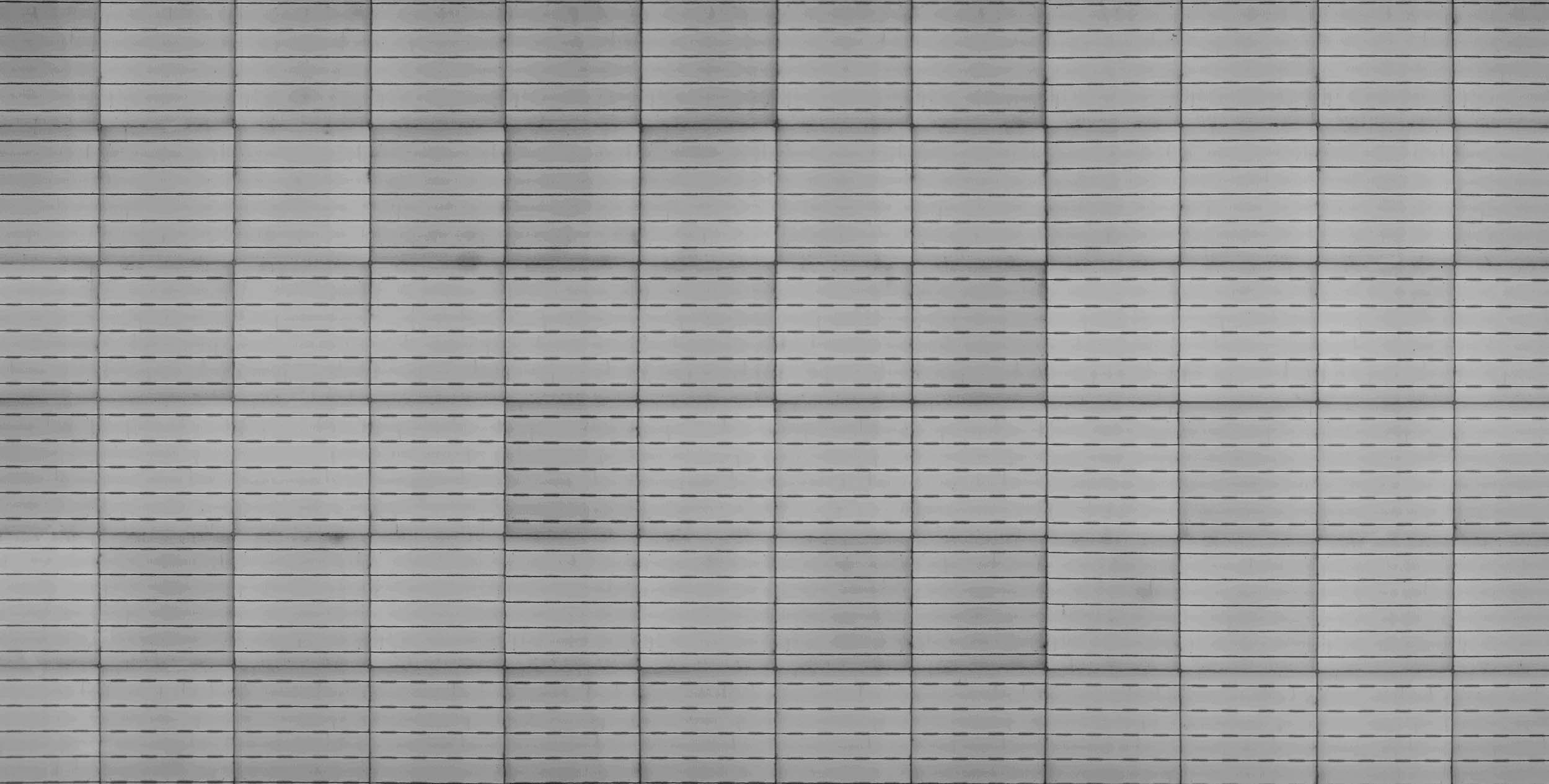

We took the records of a factory capable of taking high-end EL photography as a benchmark.

Our aim was to capture at least this image quality in the field. For this reason, a serious sensor/lens hunt started for us. Which sensor should we use with which settings? Which feature of which lens should we utilize? Which filters were necessary, we went on a long journey. In every EL photo we took, we looked for the next step, which I believe we have reached at some point. But the solution was not only hardware-based.

In addition to off-the-shelf EL hardware solutions, you also need a post-processing process to get the required values in the image, so it’s both a hardware and software problem.

So where did we come from? Good question. See below the first and the last photo we took of the same panel.

Isn’t the difference enormous? Where have we come from? Today, there is a very serious optical quality and optimization with software. We have a photographic technique that allows us to see even the finest details on the cell.

Moreover, our Raspberry device in the system can receive this data and send it to the cloud, where a python code analyzes and interprets it. Today, we developed the device you see above, we wrote the necessary photo manipulation codes and we are developing cloud applications. Maybe 5 years ago, these were dreams. Where is technology going?

Do not damage the panel while mounting the panel. All will be revealed when we come to the EL test 🙂

You can fill out the form below to get information about our EL tests.

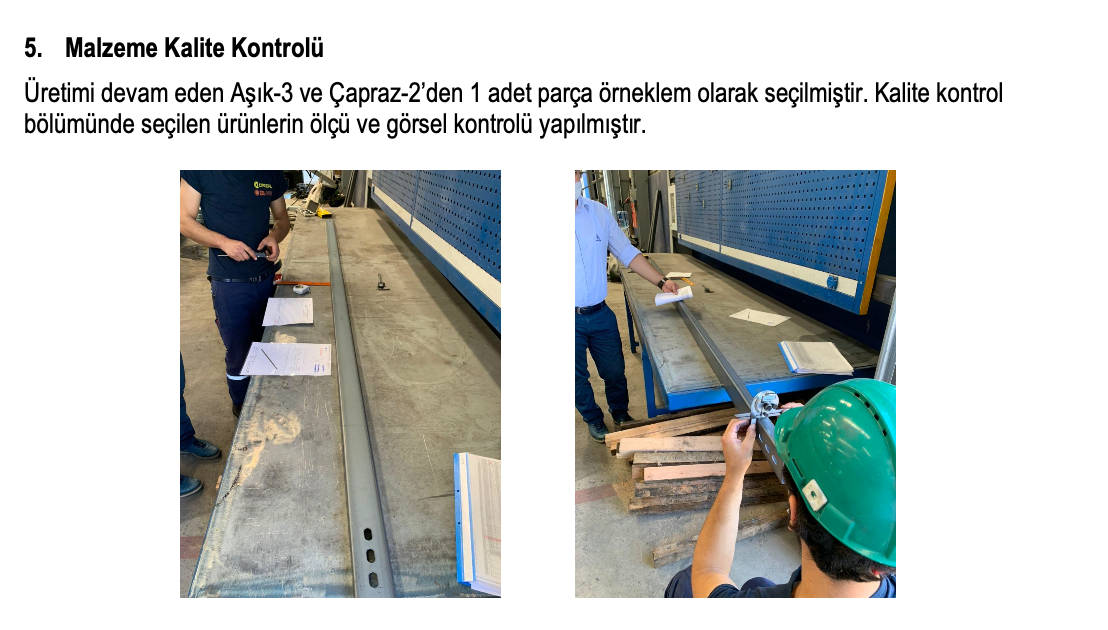

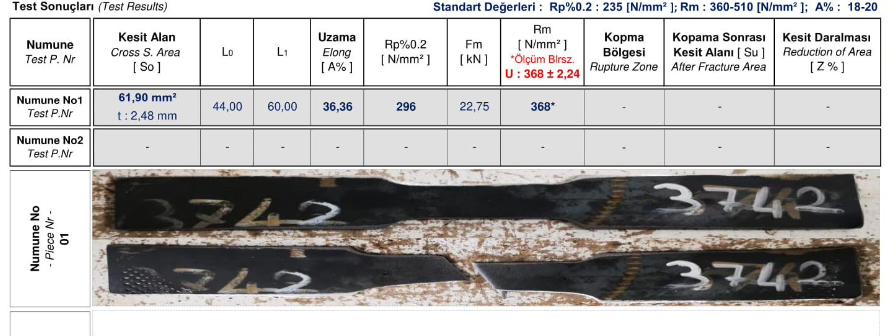

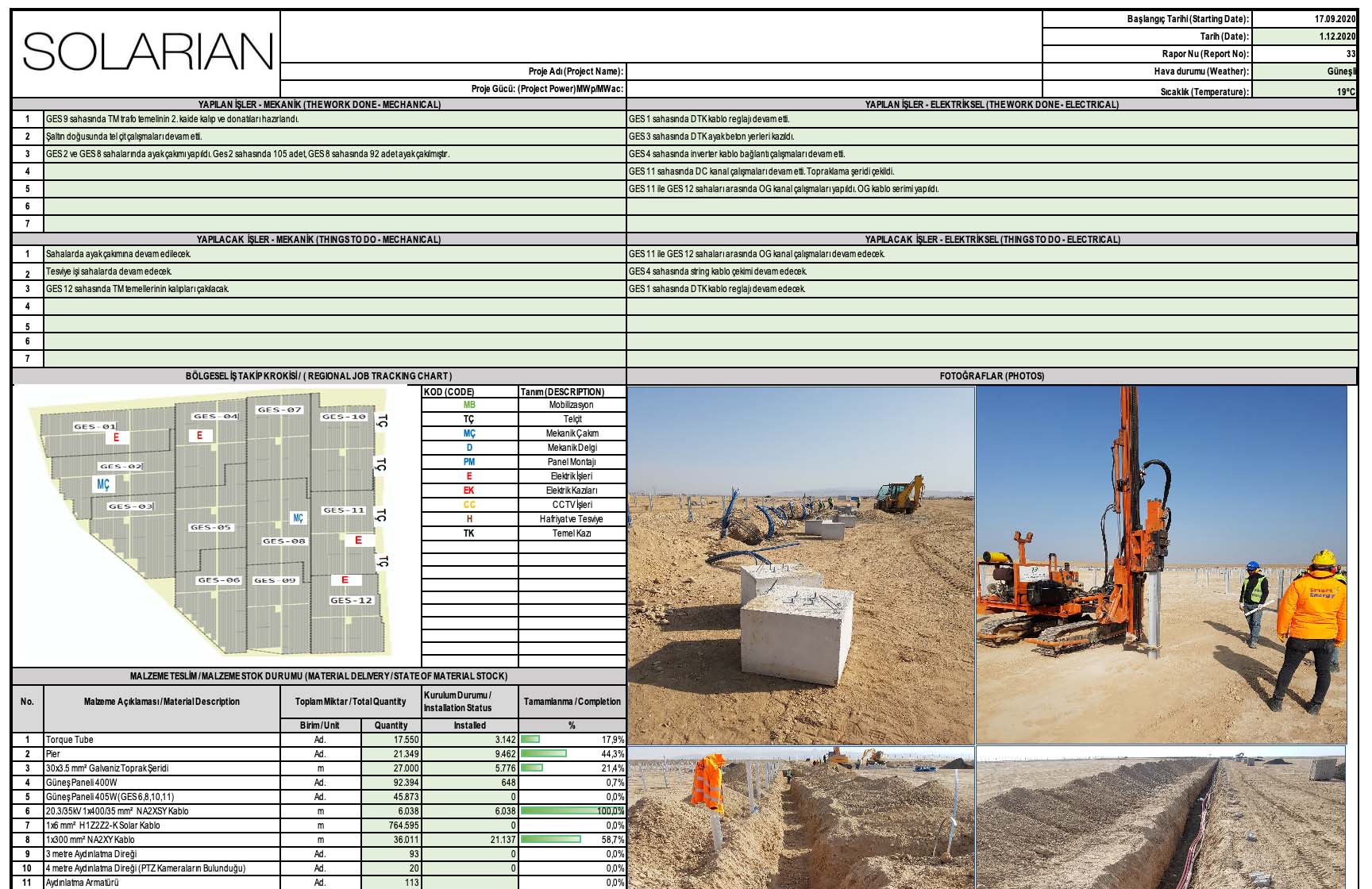

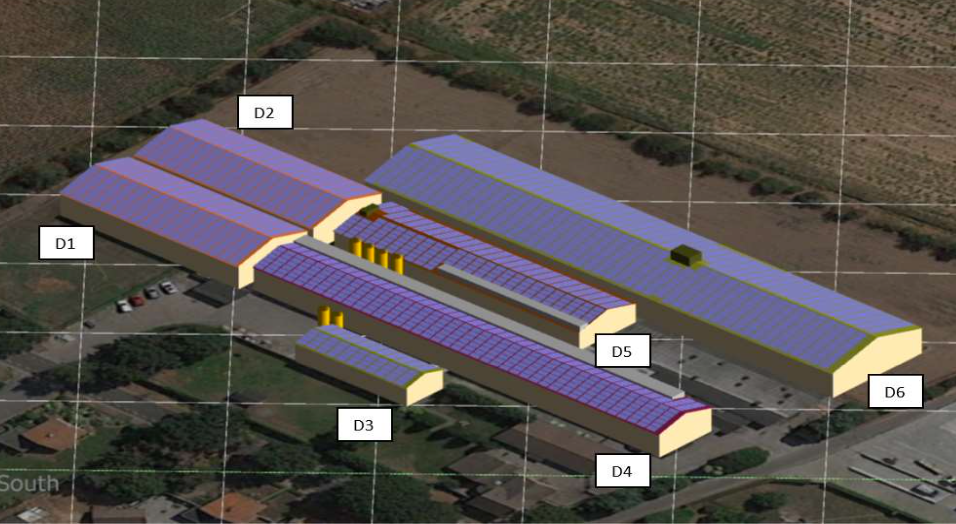

2.3. Inspection of Construction Processes

2.3. Inspection of Construction Processes