Turkey in the unlicensed solar power plants, became a popular trading commodity and reached an installed capacity of 5GW due to the dollar-indexed income scheme

However, trying to install some of the power plants at the end of 2017 with a fast pace and the use of poor quality products at some power plants brought investors in a different state.

At this stage, Solarian is offering our consultancy services to the people who want to buy or sell unlicensed solar power plants as follows.

1 – Regulatory Competency

There are many legislative problems that need to be taken into consideration during the construction and commissioning phase of the unlicensed solar power plants. Many problems can arise, including technical issues, which include both the trade issues and the commitments given during the zoning approval of the application type, the approval of the municipal construction permit. At this stage, Solarian takes over the commissioning process of the power plant from the development stage; we offer you with detailed descriptions of the risks you may face.

Power plant billing at the moment doesn’t mean you have no problems in the future from a legislative perspective.

2 – Production Performances

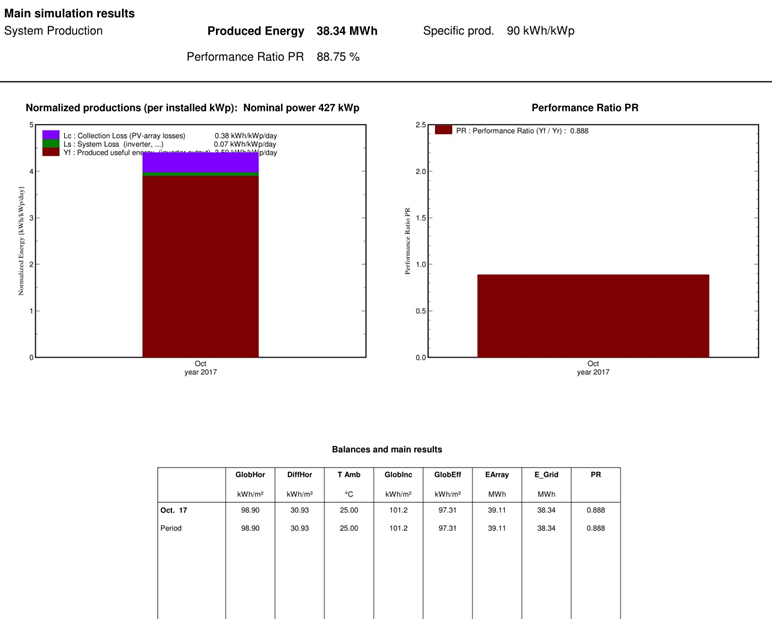

When purchasing unlicensed solar plants, it is considered as the simplest control method to look at the past 1-2 invoices and look at the desired amount and payback in a few years. This calculation is misleading. Every month of the year, solar energy falls to our world in different proportions. For this reason, a SPP plant produces different rates every month of the year.

At this stage, it should be checked whether past productions are compatible with expected production, whether this power plant produces the energy that it needs to produce, or whether it is subject to loss of energy (power transmission line, transformer problems). As a result of this study, it is learned clearly how much a debt payment the plant can overcome and how much it can pay to its investors.

The fact that the power plant is able to pay its debt with the production in the past does not mean that it continue that again .

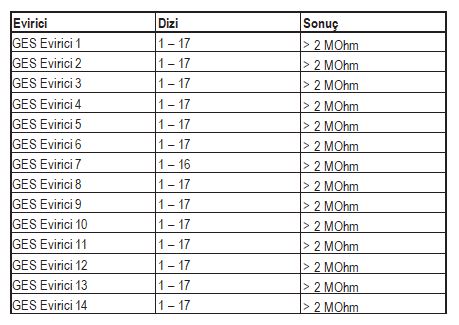

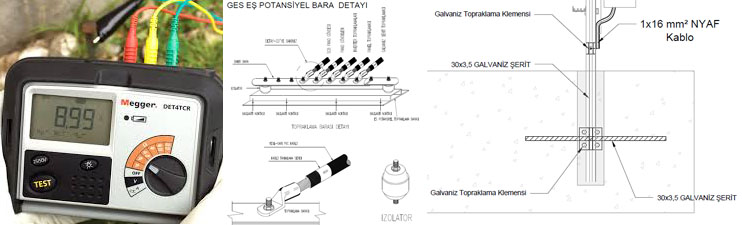

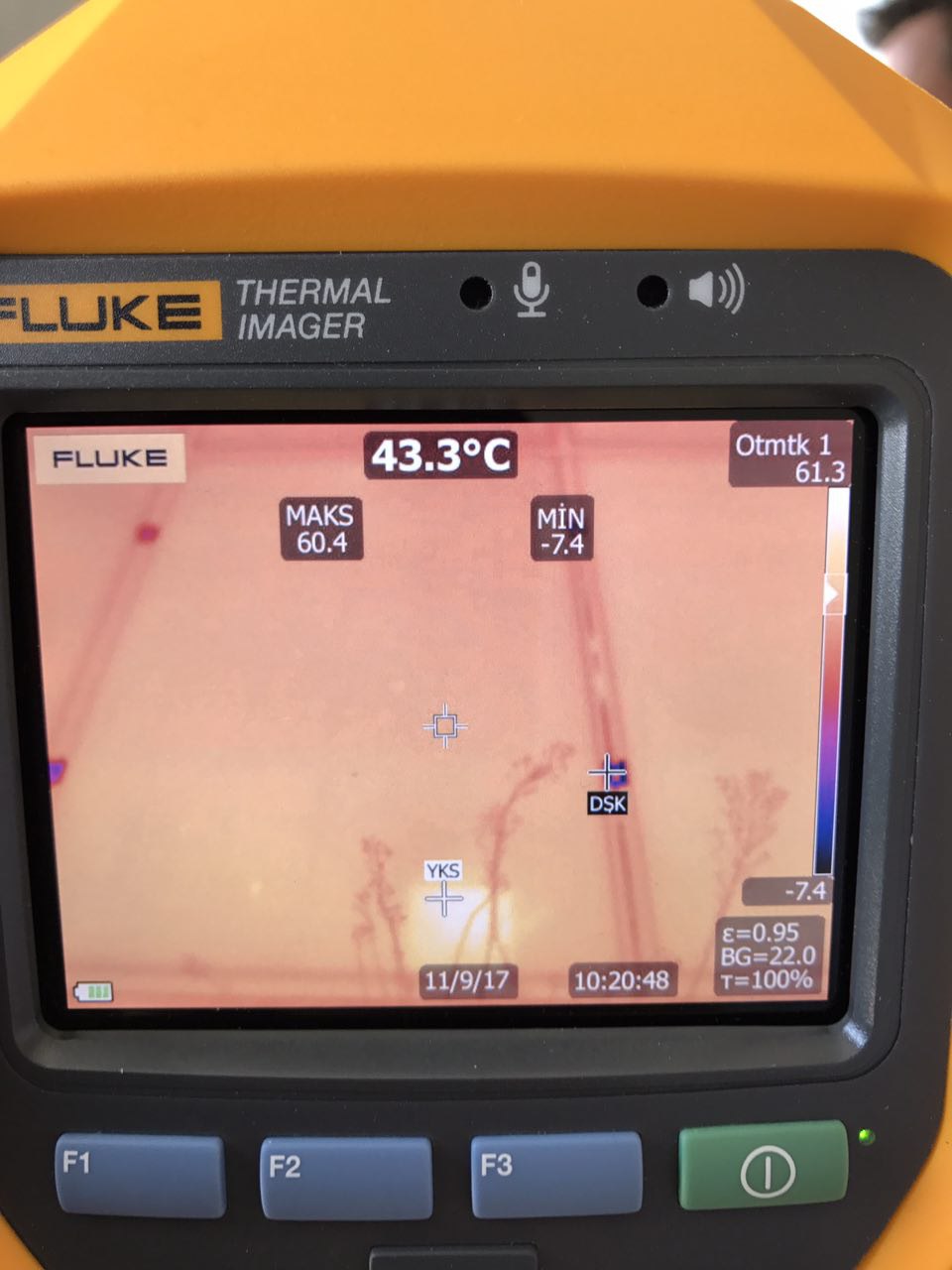

3- Field Tests

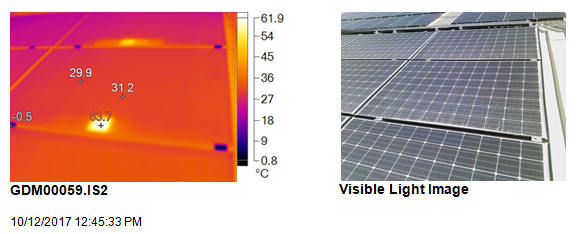

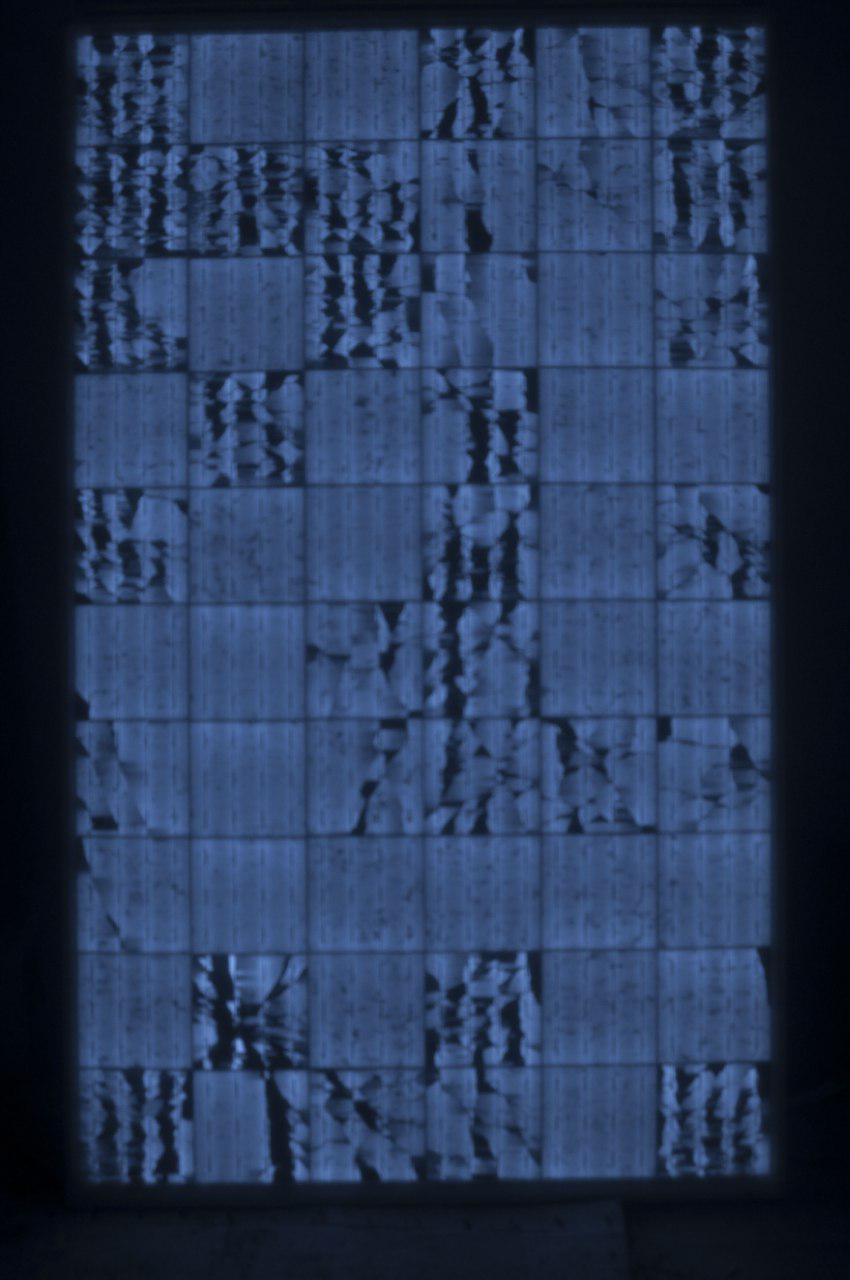

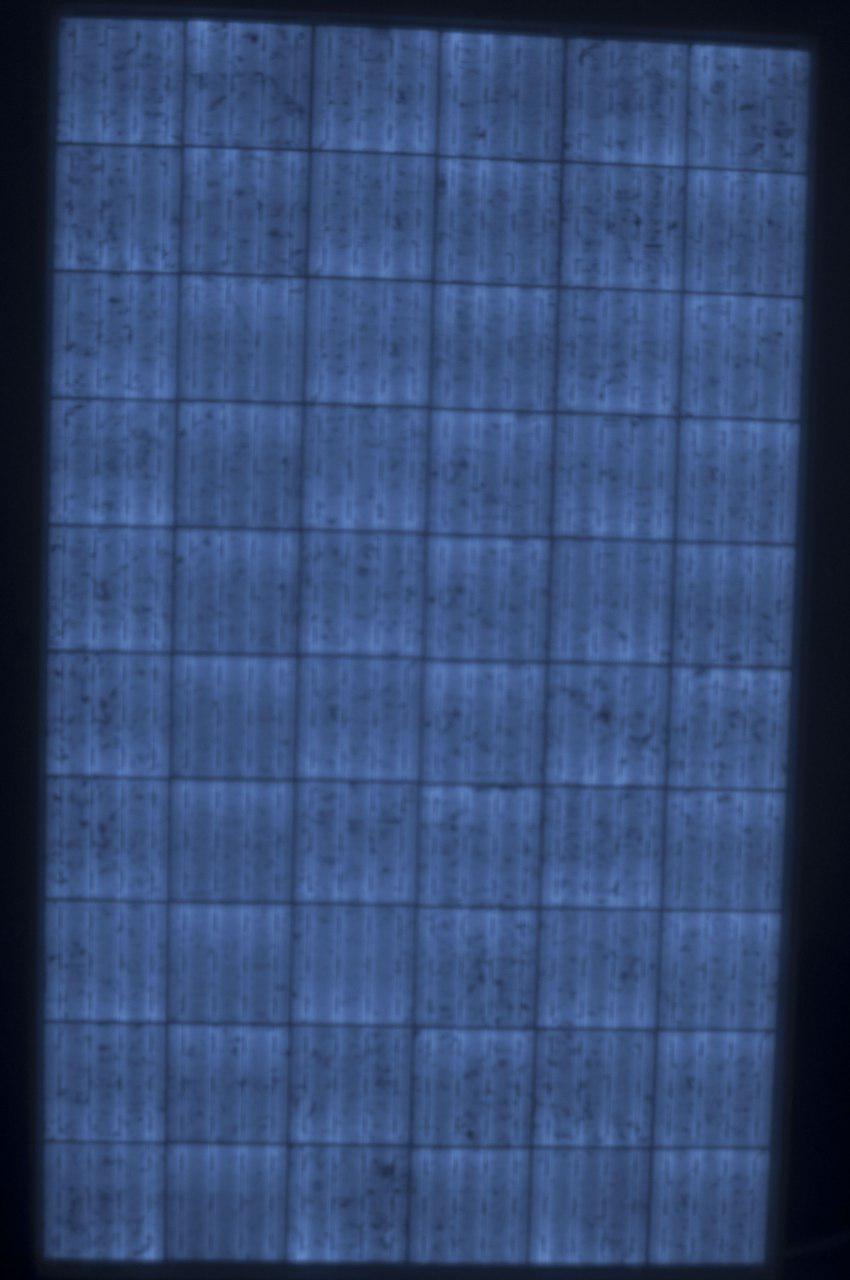

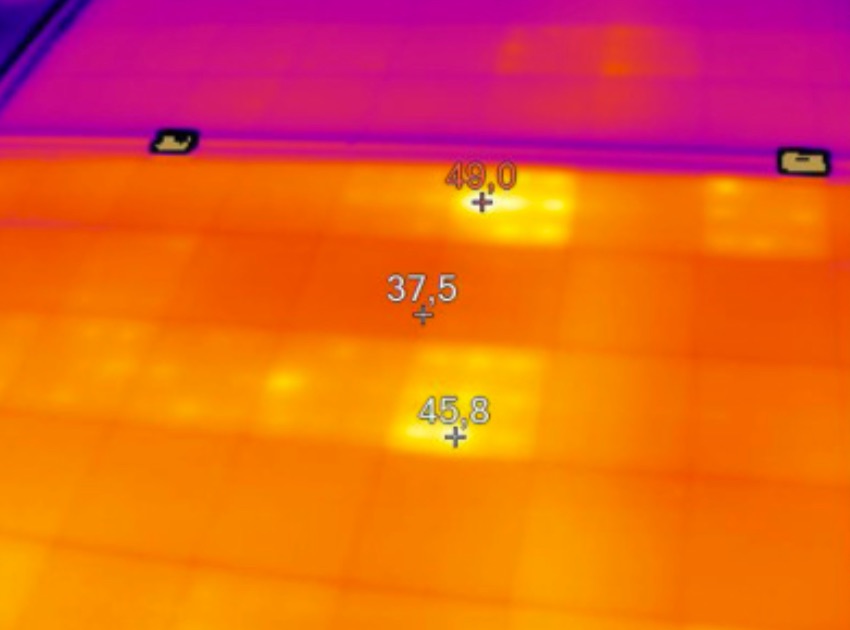

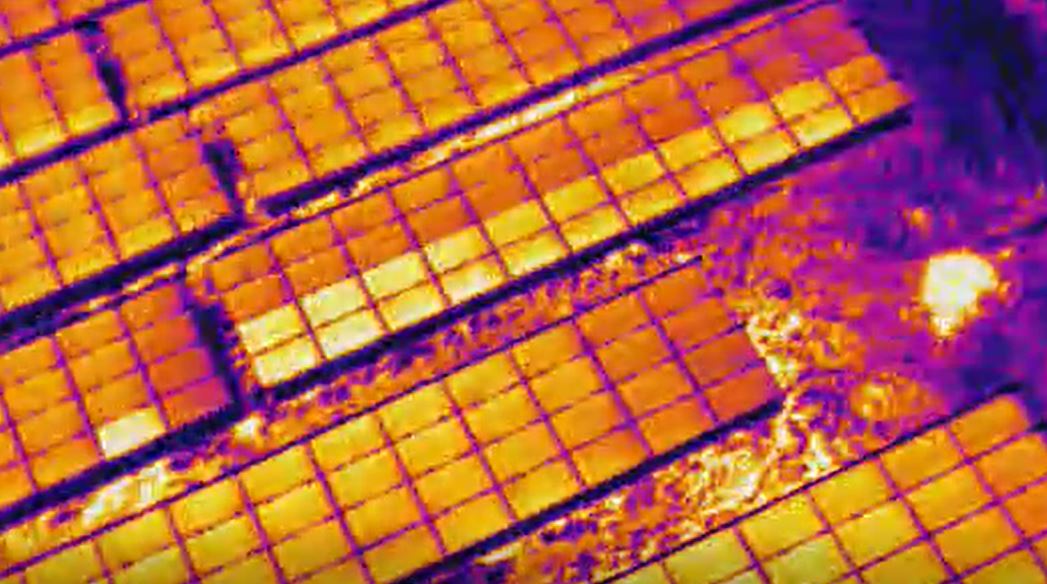

The products used in solar power plants are expected to have a life span of about 25 years. However, many products are being damaged in the first two years, and they are far below the performance they should perform. There are traces of snails on the solar panels, cracks and hot spots are formed. In the first two years, these problems cannot be noticed.

In the field inspection, we test the technical situation of your solar power plant with the other specific tests and measurement devices and report, if there is any other damage. At this stage, you may have learned and prevented the potential problems of the solar power plant you bought at the time of your plant’s production.

Although the paperwork suitable for the guarantee and solar panels can also available in Turkey or elsewhere, in accordance with customs regulations some brands no longer be able to bring goods to Turkey. Having a warranty certificate does not mean that you can benefit from this warranty.

In this context, if you want to buy an unlicensed solar power plant, you can contact us by filling out the form below

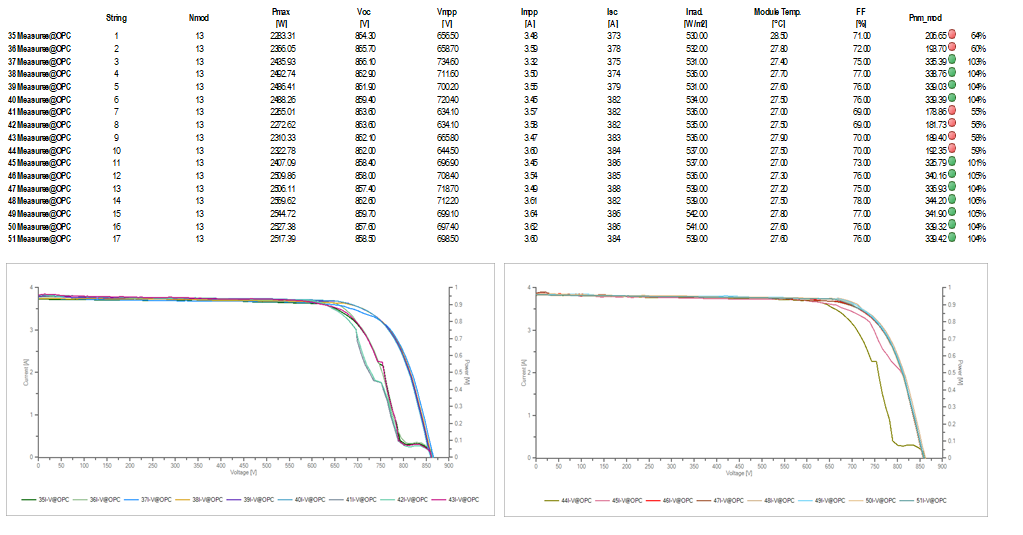

The raw data of the sensor data [/ caption]

The raw data of the sensor data [/ caption] An example of the data we followed on excel before transferring it to the software. [/ caption]

An example of the data we followed on excel before transferring it to the software. [/ caption]

EL Test [/ caption]

EL Test [/ caption]