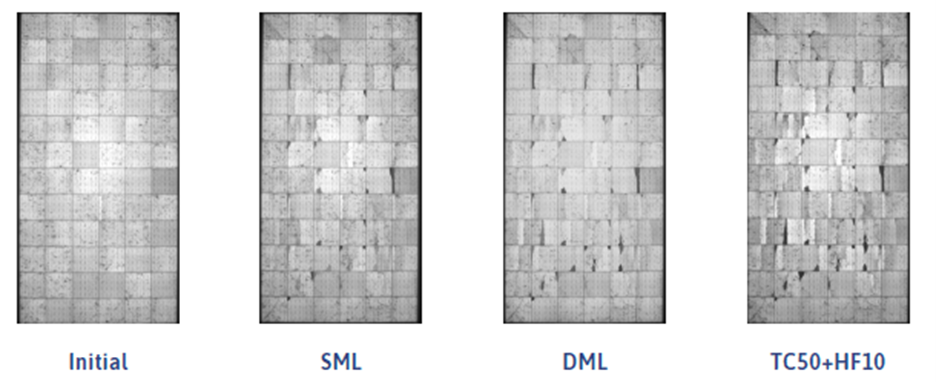

When Solarian was first established, we were offering our thermal drone services, but the results we got with the gimbal-less flir camera mounted on a Phantom 4 were very bad. After using it for a few jobs, we didn’t use it again and continued with the standard method of hand thermals.

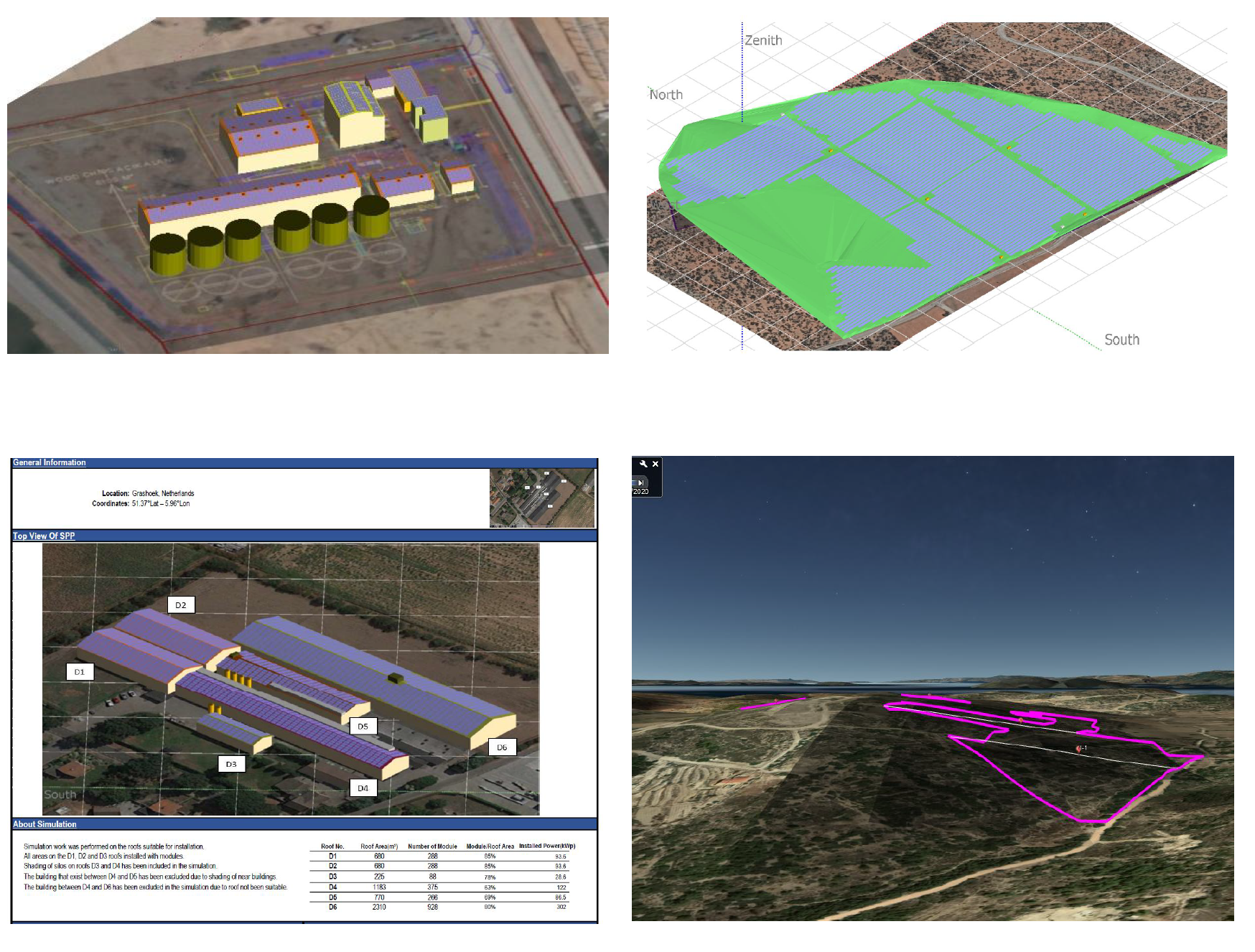

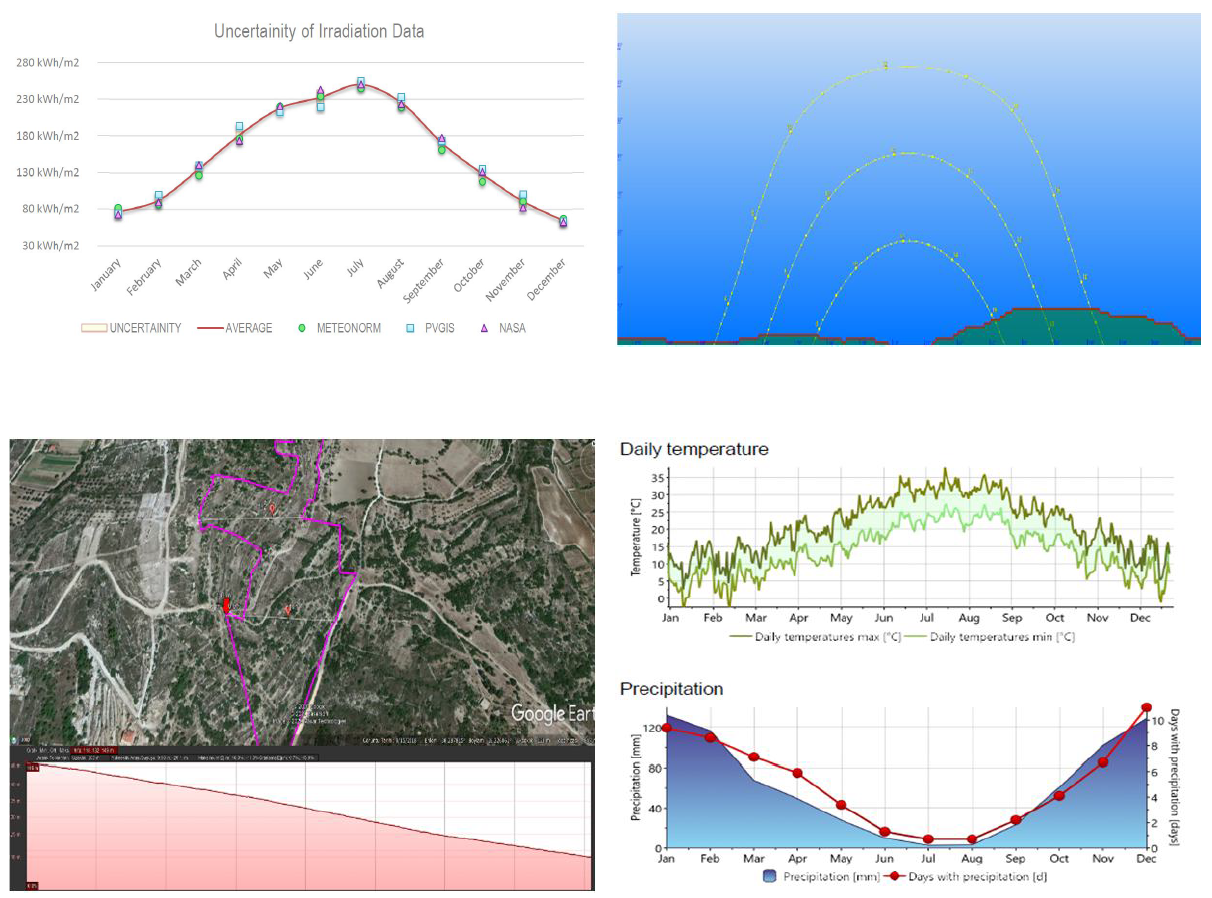

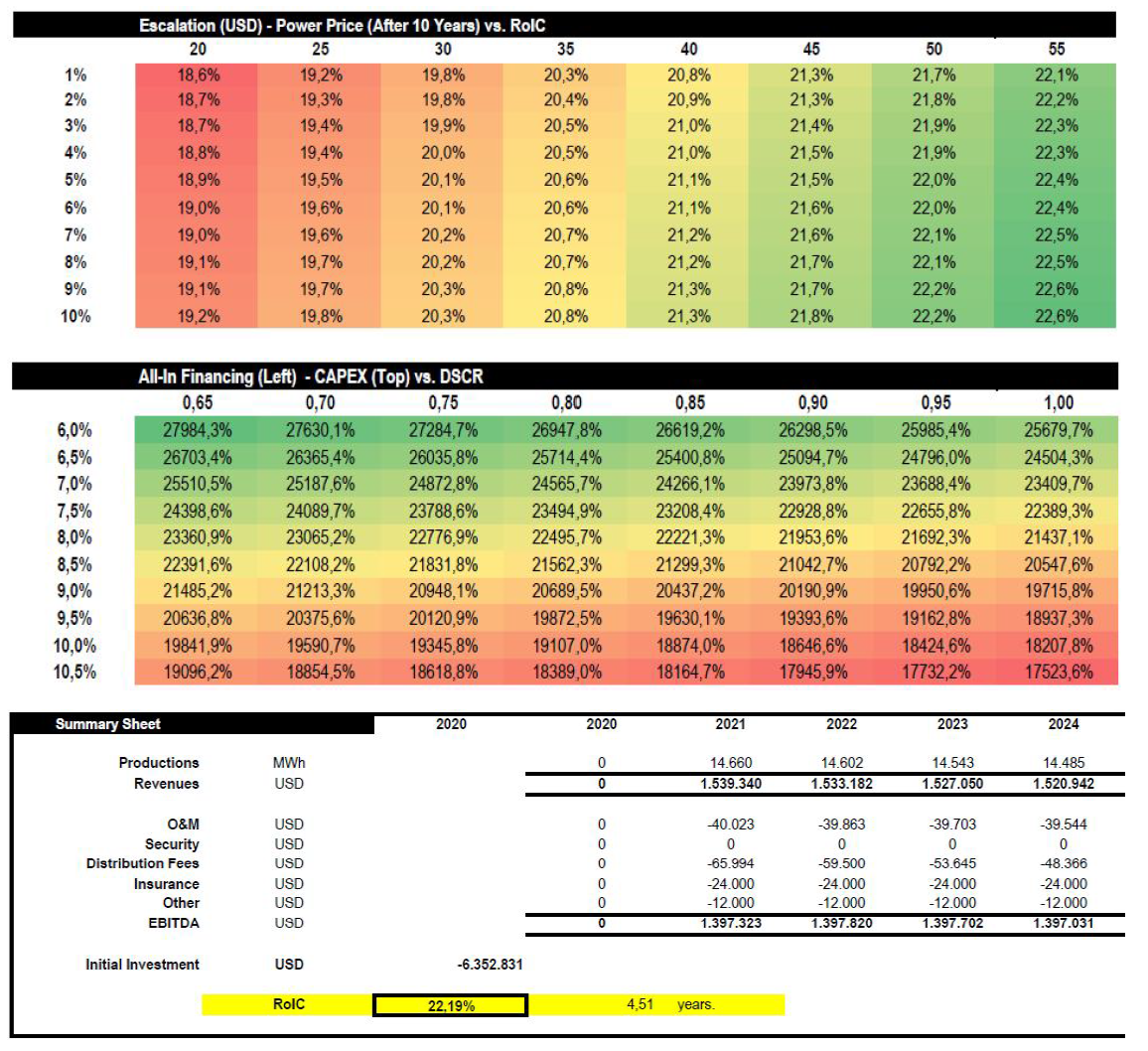

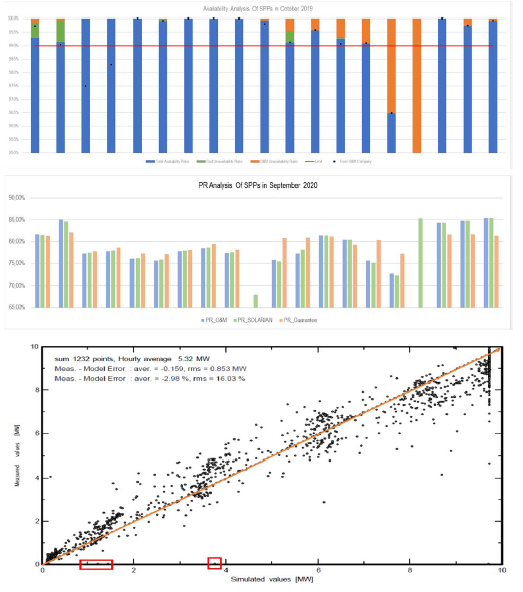

It has been 4 years since then and technology has advanced. Where we were doing PVSYST analysis, we were able to use drones to read the ground topology and transfer it to PVSYST, so we could get much more precise results from energy production analysis. We had made so much progress in orthophoto that we started to think why not use this technology in thermal.

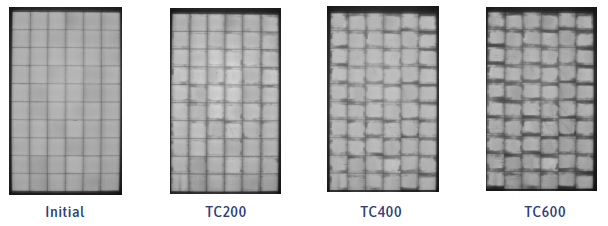

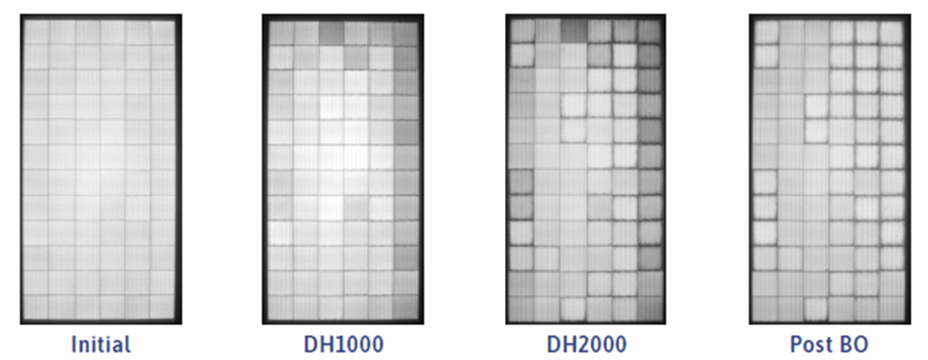

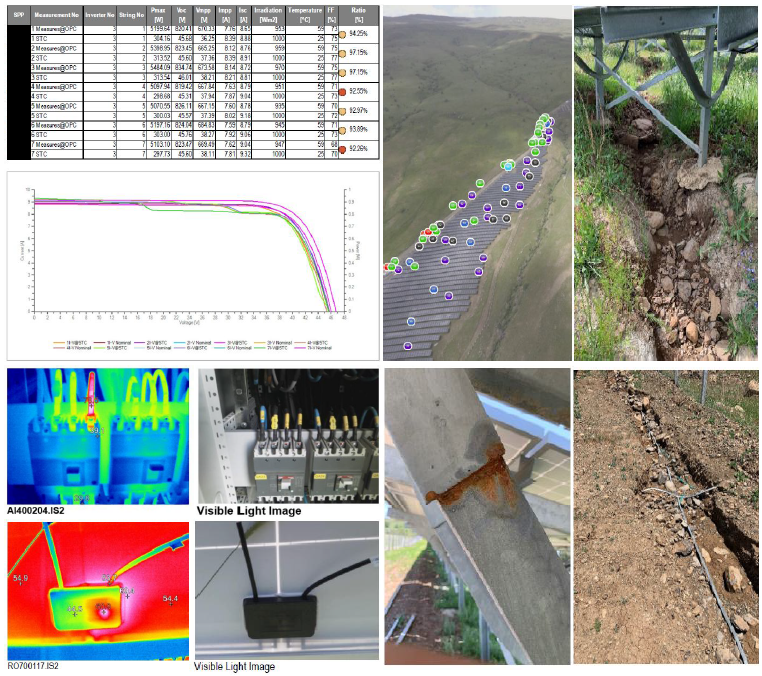

For orthophoto to be good, you need high resolution. The cameras we currently use for ground topology are at the 50mpix level, but one of the best thermal resolutions is 640×512. With this resolution, you can perform thermal inspection in accordance with the IEC 62446-3 standard from a distance of about 20-25 meters. The standard requires a minimum area of 3cm per pixel (3cm/px). Even with this resolution, you may need to fly for about 30-45 minutes for 1MW SPP. If you use a 320×240 camera, a flight of 2.5 hours is required for 1MW SPP (if it will be done in accordance with the standard). Not to mention the 160×120 camera.

Of course, this flight is not easy to do manually, so you also need to use software to automate the drone flight. It did not take us long to realize the suitability of our technology, which we developed in the past years to make energy production analysis more precise.

Of course, in this situation, it did not take long for us to switch to the approach of “There is flour, sugar, oil, let’s make this halva”.

First test route? Seychelles

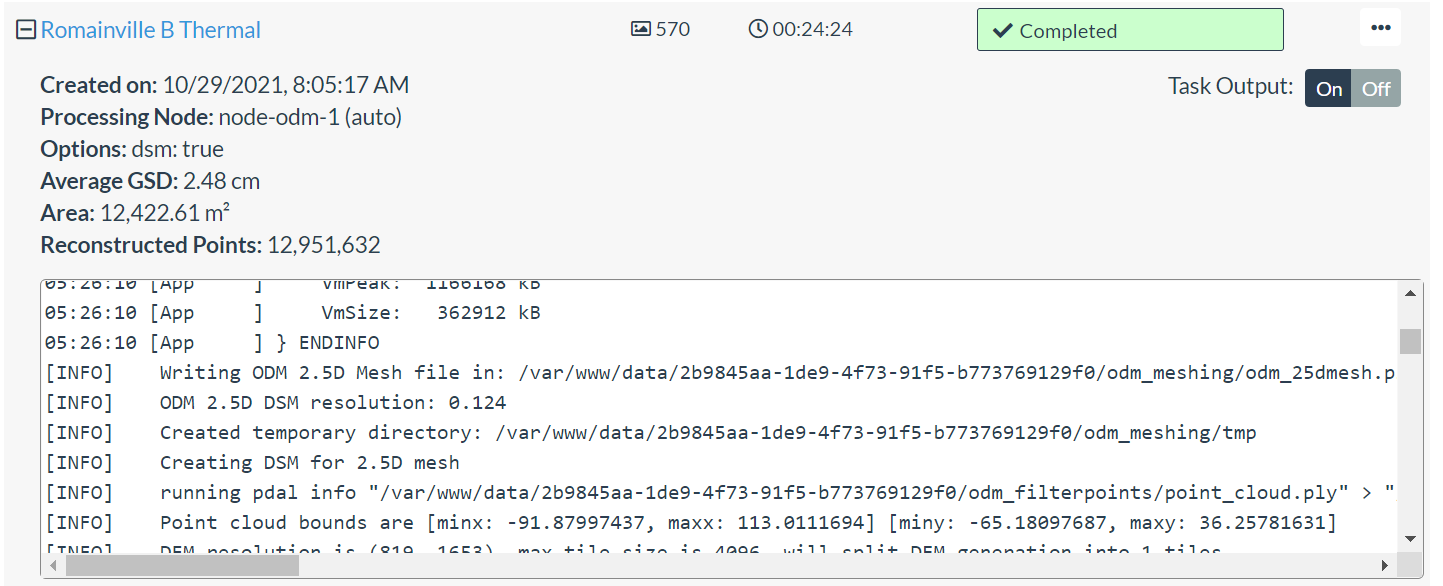

We tried our first thermal drone flight on the island of Romainville in the Seychelles, where we went to provide services for a Masdar project under IEC62446. We took photos from different angles and different overlaps and tried to get the best. We had countless trials and errors.

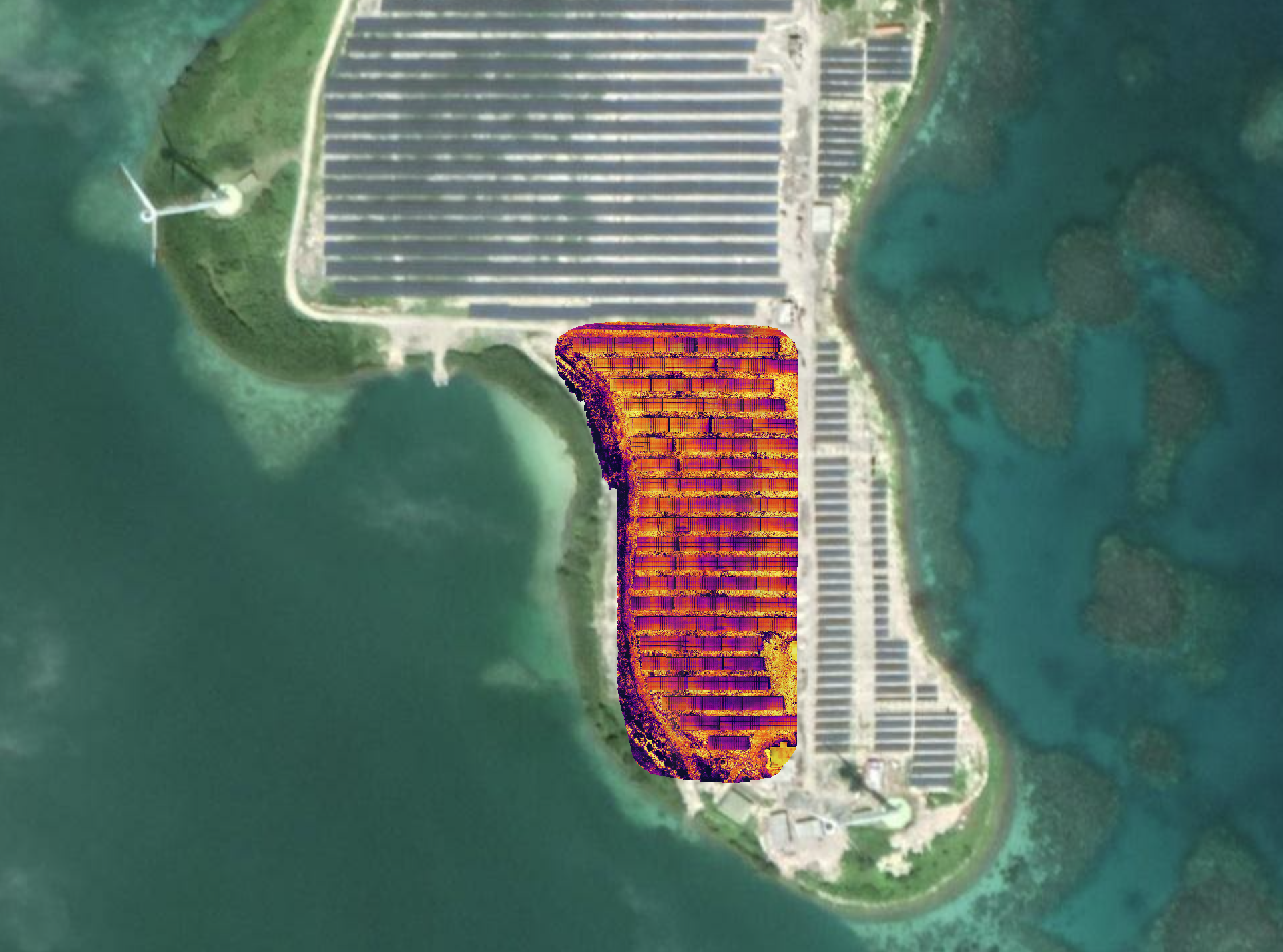

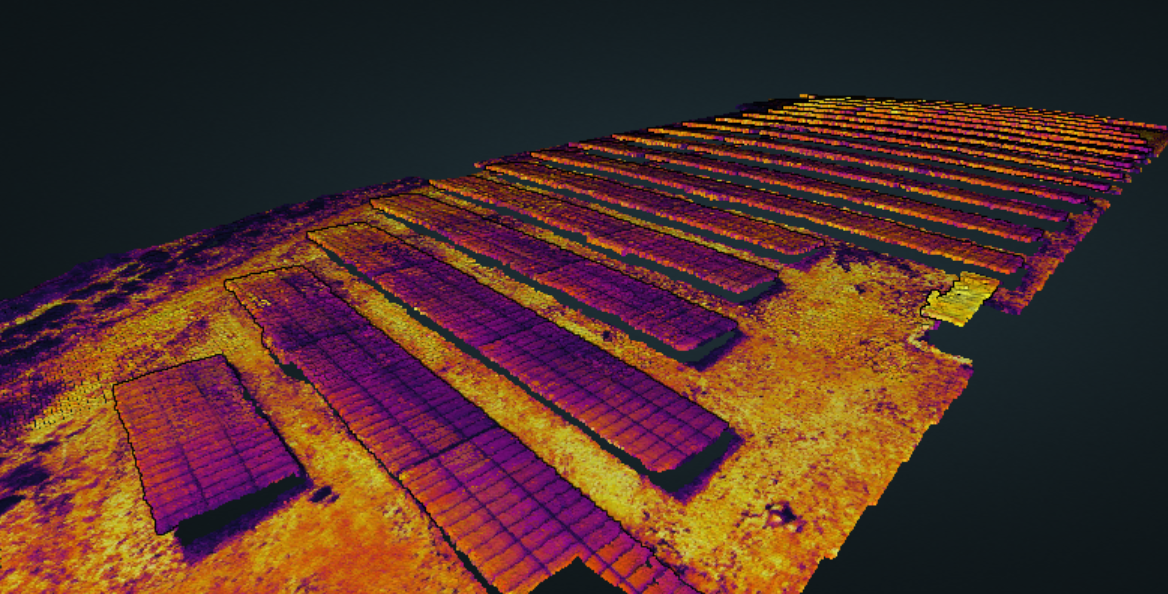

When we finally completed our work, we obtained a thermal image superimposed with Google Earth as shown below.

We even went one step further and created a navigable 3D thermal model.

If you want to create a 3D thermal model of your SPP plant and examine it in detail for errors, contact us.

[hubspot type=”form” portal=”20030422″ id=”60a2a1b1-7bc0-4c65-bac1-f5c05c255f3b”]