In order to ensure that the solar panels produced are durable, solar panel factories carry out production monitoring throughout the entire production process, including pre-production, production period and pre-shipment. This ensures the quality of the solar panels produced for your project.

There are three standards that interpret the product quality of solar panels. These are IEC 61730, IEC 61215 and IEC 61446. However, these standards specify minimum quality conditions. For this reason, each of the factories producing solar photovoltaic panels has its own quality acceptance criteria. It is important to determine these acceptance criteria based on engineering fundamentals and specific to the solar panel to be produced for the project.

Certified solar panels indicate that the solar panel manufacturer meets the quality and safety requirements of the certification bodies on the specified product. However, this approval is only possible if the specified raw materials are used and if these raw materials are stored in the warehouse in the correct climatic values.

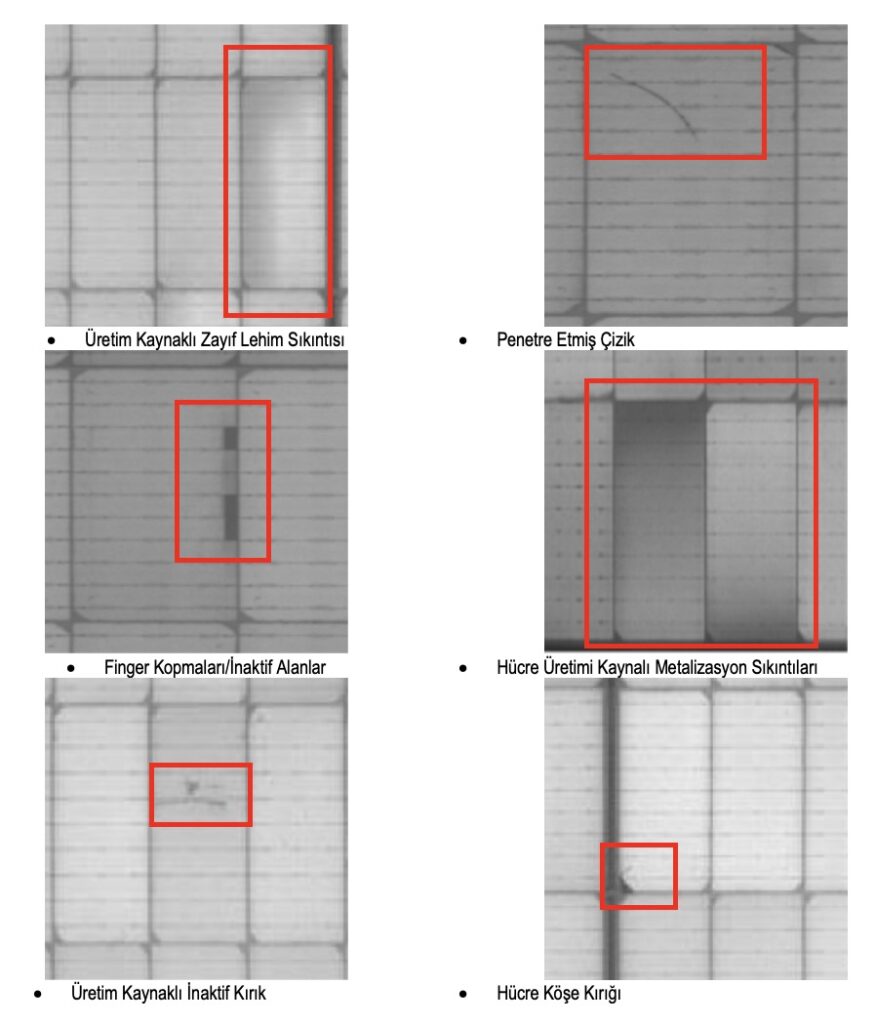

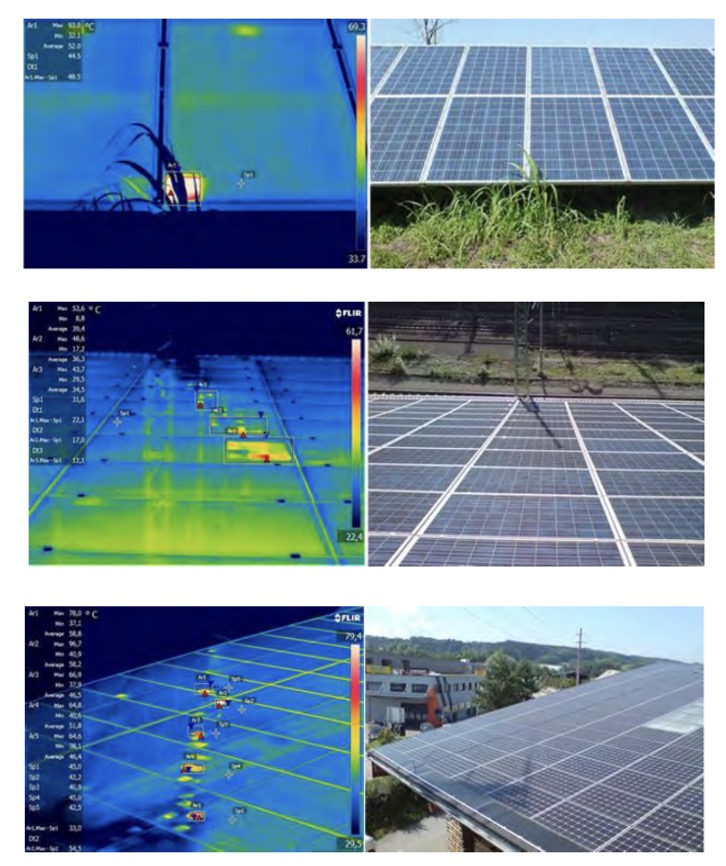

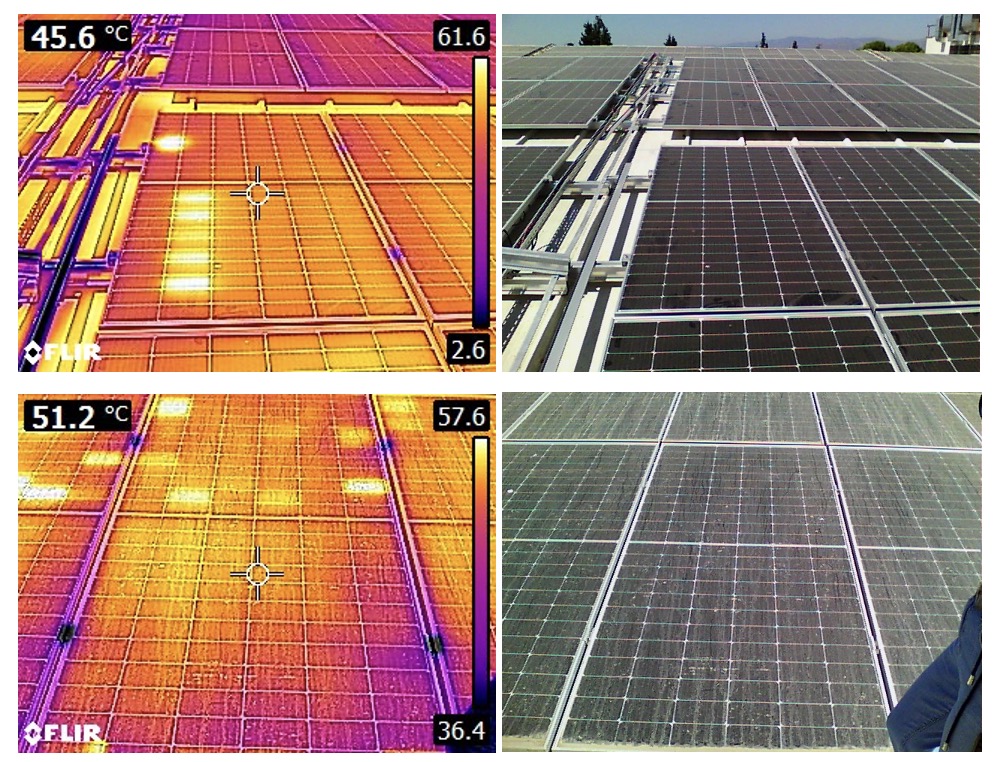

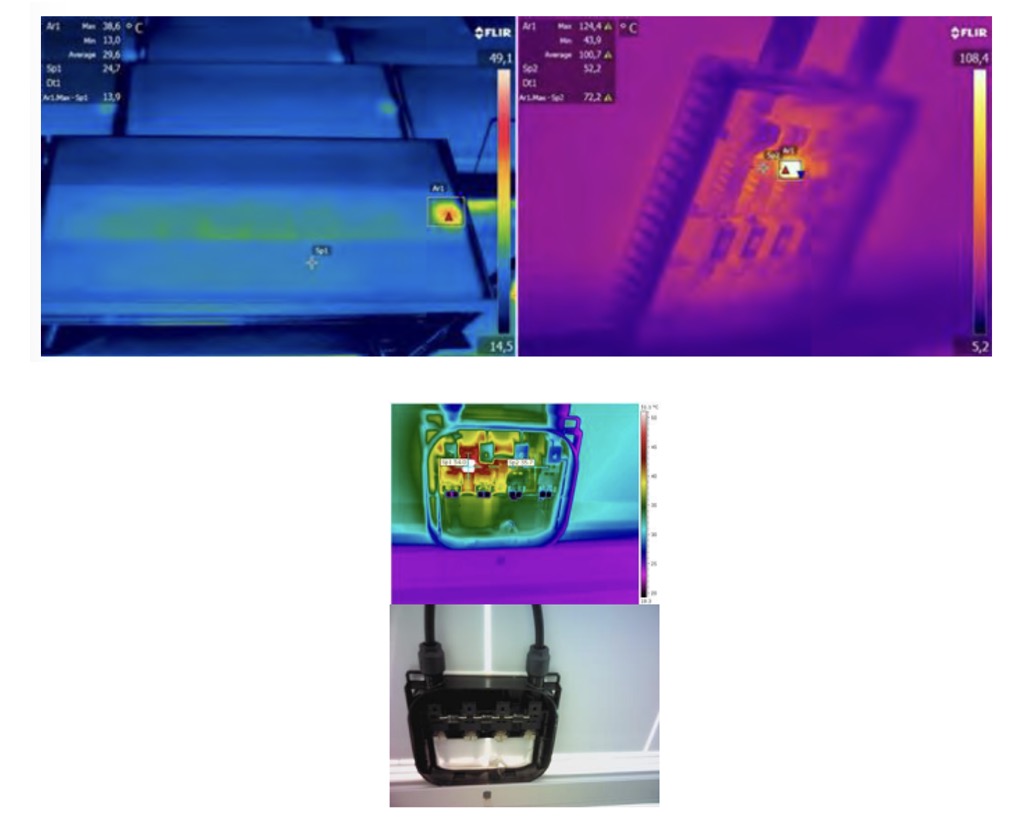

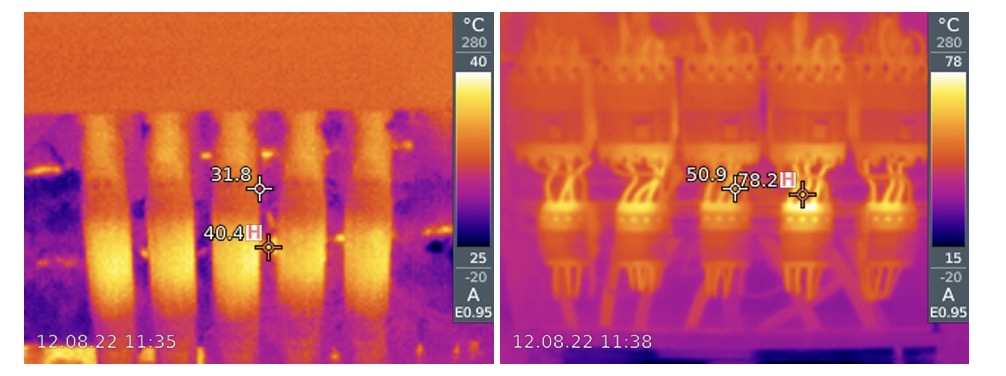

If the inspection is not carried out at the solar panel factory, the possibility that the solar panels have physical defects causes the lifetime of the solar panels to decrease. In mass production factories, it is very important that the production line is controlled by an outside eye. In addition, not all solar panels produced have the same electrical values. Solar panels that provide the committed values for the project must be selected and prepared for shipment.

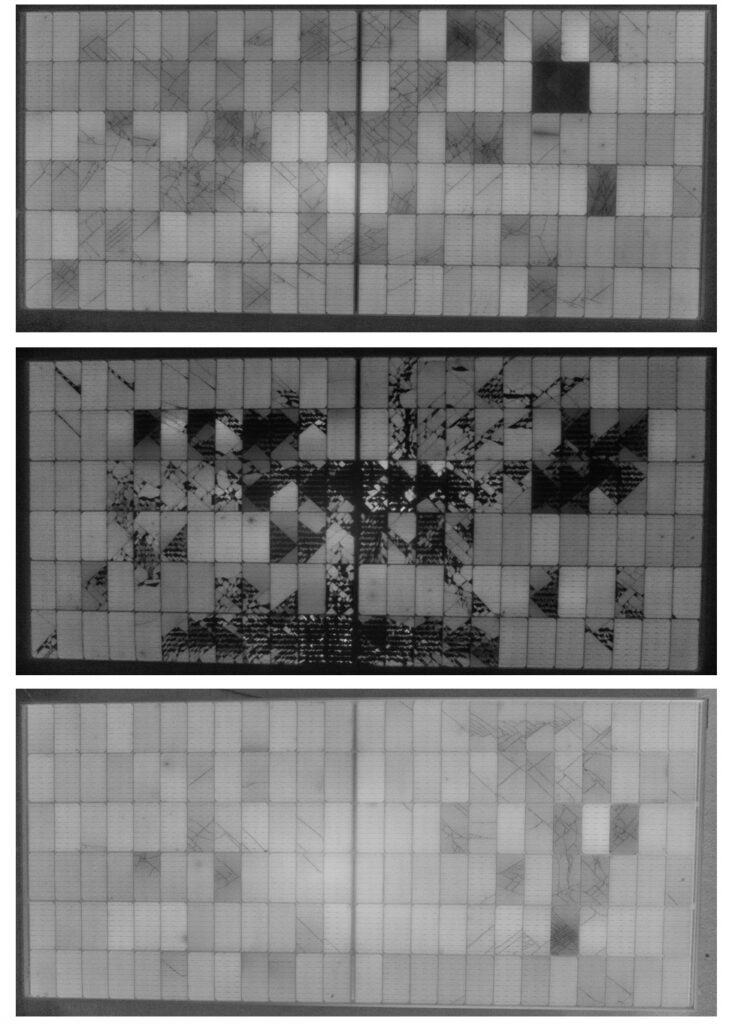

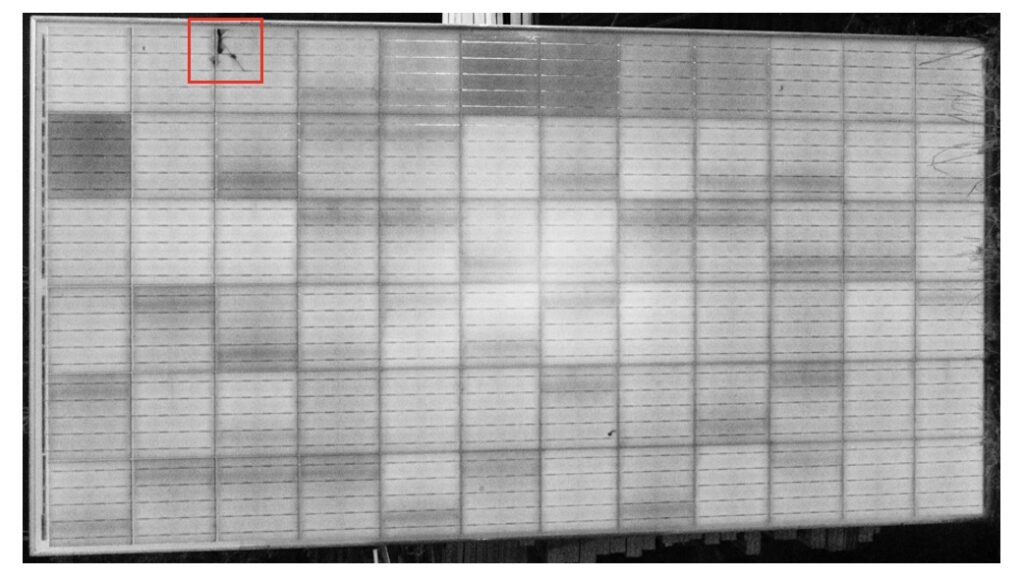

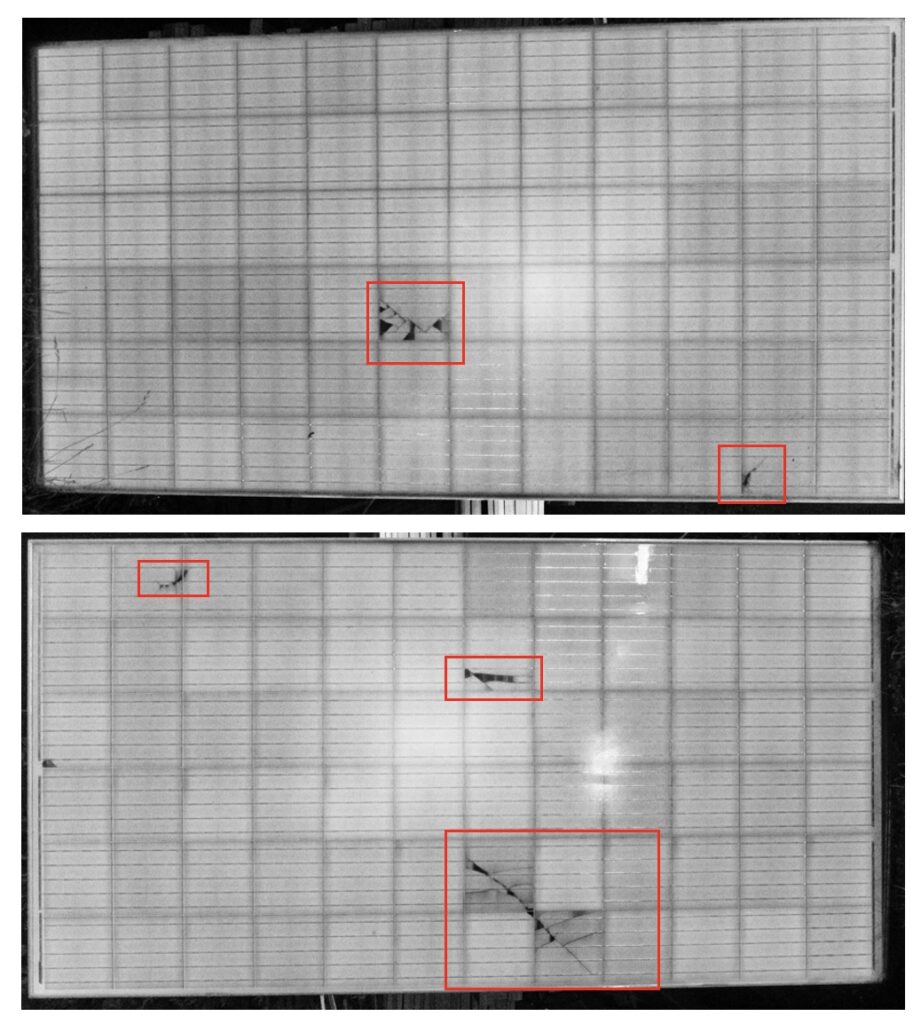

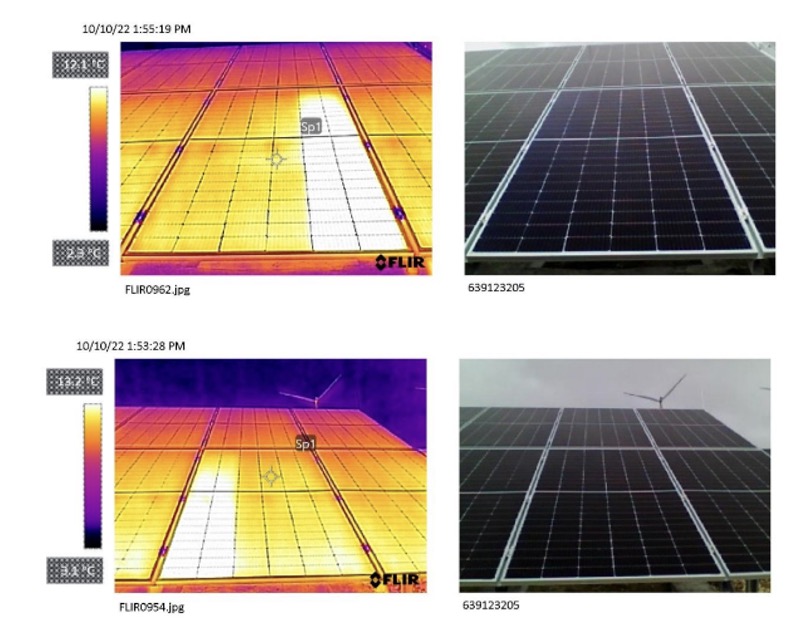

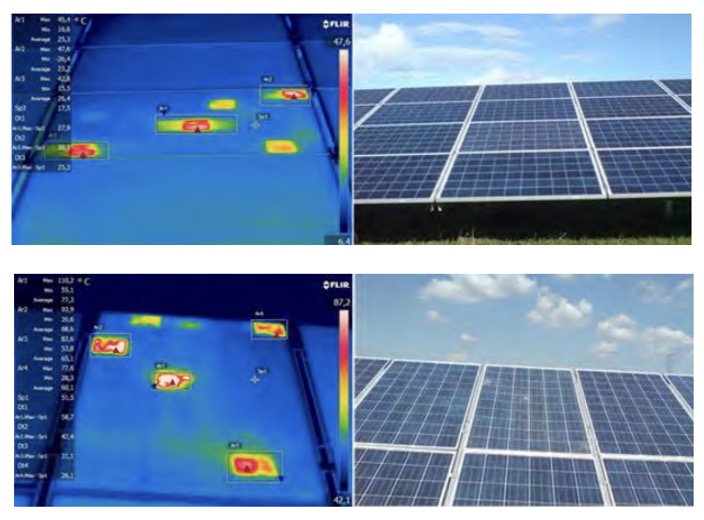

Not all defects of solar panels can be visually appreciated, THE visual control must be performed by experts. According to the determined acceptance criteria, the solar panels suitable for the project must be inspected, selected and prepared for shipment.

Preparation for shipment is the last stage in the procurement of solar panels with a high probability of error. It is very important to determine the precautions to be taken to eliminate the risks of physical damage during the transportation of solar panels to the field and to carry out the manufacturing inspection of PV modules in this process.

If you want to ensure the quality assurance of the solar panels to be produced for your project, you can contact us. Solarian’s engineering and inspection team is ready to support you on manufacturing inspection during the production of solar panels.

Fill in the contact form to get in touch with us.