Photovoltaic solar panels constitute a large part of the solar power plant investment amount. At the same time, many performance and safety tests are applied to these solar panels by the relevant laboratories as there are many types of defects that cannot be seen by the eye. The IEC 61215 standard includes minimum design criteria that will affect the performance of solar panels, while the IEC 61730 standard focuses on design criteria that will affect plant safety in solar panels. The rapid development of technology brings along product diversity. For this reason, the International Standard Commission is developing test scopes and test diversity day by day. The IEC TS 63209-1:2021 standard is the first standard created in this context and includes a wide range of solar panel tests to comment on the long-term performance of solar panels.

Solar panels are entitled to receive a certificate if they successfully pass the tests according to IEC 61215 and IEC 61730 standards. Although all solar panel tests written in the standard are important, the definition of some tests is as follows.

Firstly, the power, temperature coefficients, insulation resistance, thermal measurements of the photovoltaic solar panel are checked with performance tests in accordance with IEC 61215 standard. After the performance tests, solar panels are subjected to aging tests under certain conditions. Below are examples of solar panel tests.

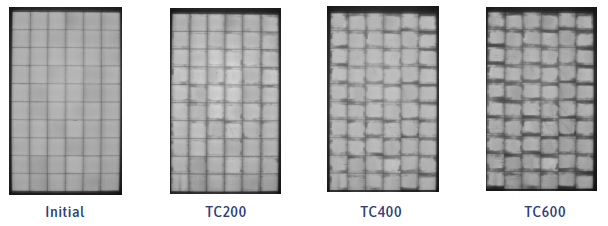

Thermal Cycle Test: The performance of photovoltaic solar panels at variable temperatures is tested successively by passing current between -40°C and +85°C through the solar panel. The damage to the solar panels due to test repetition is as follows.

Humidity Freeze Test: At high humidity, the ambient temperature is first raised to +85°C and then lowered to -40°C. This test is repeated consecutively. In this way, performance in freezing humidity is evaluated.

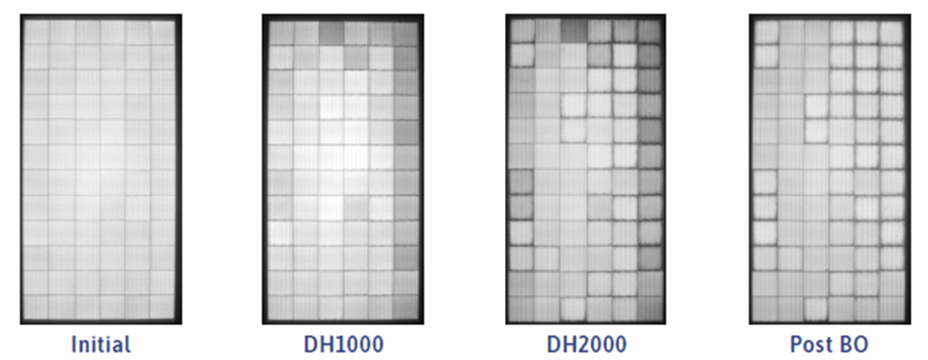

Damp Heat Test: Photovoltaic solar panels are kept at +85°C and 85% humidity for 1000 hours. The damage to the solar panels due to test repetition is as follows.

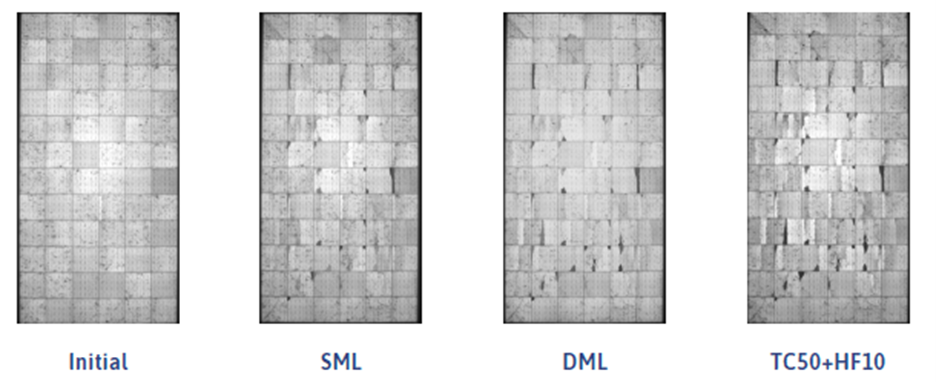

Mechanical Loading Test: At a minimum of 2400Pa, the front and back surfaces of the solar panel are pressurized in a row.

Photovoltaic solar panels are subjected to performance tests again after the aging tests mentioned above. In this way, the long-term performance capability and the amount of degradation of the solar panels are revealed and if they pass, they are certified.

In addition to the above tests, a PID test should be applied to solar panels. As the solar panels operate, sodium ions react with the potential formed on the conductive layer and the glass surface and a positive charge accumulates on the panel surface. This interaction is called PID and the loss it creates is called PID loss.

The solar panel quality control process respectively is as follows.

Pre-Production Control of Certificate and Annexes

Each solar panel with different technology and power coming out of a factory must be subjected to the solar panel tests specified in the standards. The certificate obtained for one solar panel cannot be used for another solar panel. For this reason, solar panels should be checked by expert engineers on the production line before they arrive at the site. This control first starts with the control of the certificate and its annexes for the solar panel to be used. All raw materials specified in the certificate, certificate annexes and raw material list must be valid and consistent with each other. If there is a discrepancy between these documents, there is a possibility that the solar panel is not certified.

Factory Control in the Production Phase

There are many controls that need to be carried out during photovoltaic solar panel production. These are the raw material warehouse, air conditioning, production line and shipment controls respectively.

It also accompanies the solar panel factory tests. It is very important to check the EL visual and Flash Test results that give the power value of the solar panel. EL and Flash Test results of all solar panels are checked. These checks and interventions extend the life of the solar panel and allow the factory to determine whether the solar panels are at the promised power.

After the production of solar panels in accordance with the standards and certificates is checked, their delivery to the field is approved.

Control of Photovoltaic Solar Panels in Power Plant

It is possible to measure the performance of photovoltaic solar panels with tests performed at the power plant. These tests are IV curve measurement, hot-spot measurement with drone and hand thermals – IEC 62446, hand (electroluminescence) test of solar panels – IEC 61215 / IEC 61646, insulation (hipot) tests – IEC 62446, grounding value measurement. You can reach our detailed sharing about the measurement services applied to solar power plants according to IEC standards here.

Benefits of SPP Audit by an Accredited Company

Solarian Enerji A.Ş. is a type A inspection body with TURKAK accreditation with file number AB-0649-M. The scope of accreditation includes all the standards mentioned above such as IEC 62446, IEC 61215, IEC 62730. You can access the full scope here . By having your solar panels inspected by our TÜRKAK accredited company, you can have information about the status of your solar panels and have an accredited inspection report valid all over the world. Fill out the form below to contact us.