Solar simulator is a critical measurement system that determines the current-voltage (I-V) characteristics of photovoltaic (PV) modules, determines the power and current class by performing measurements on all panels on the production line for the electrical data on the product information label, and its features are determined by the IEC 60904-9 standard.

Solar simulators actually mimic sunlight in a laboratory environment and are used to determine the efficiency, power output and performance of solar panels. This information is critical to improve the design and manufacturing process of solar panels, verify compliance with standards and provide consumers with reliable information about the solar panel.

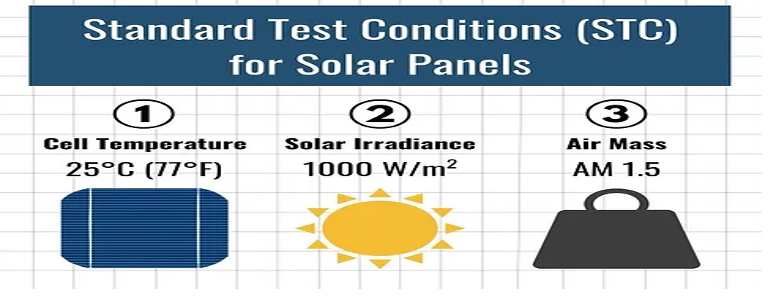

Solar panel parameters are measured under standard test conditions (STC). Standard test conditions under IEC 61215 for panel testing include;

What parameters can we obtain from the simulation?

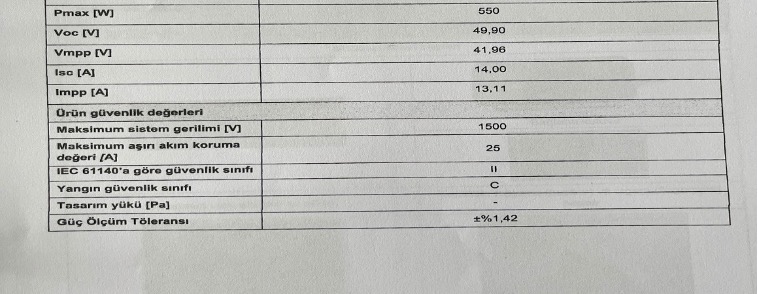

Solar Panel Power Measurement Results

- Maximum power output (Pmax)

- Maximum power point voltage (Vmpp)

- Maximum power point current (Impp)

- Short circuit current (Isc)

- Open circuit voltage (Voc)

- Series resistance (Rs)

- Module efficiency (Eff)

- Temperature coefficient

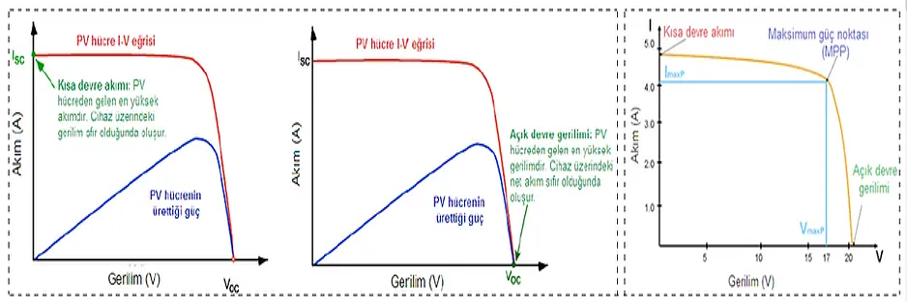

Solar Panel IV Measurement Results

Using the Solar Simulator we also obtain the current-voltage (IV) curve, which is used to determine the performance and electrical characteristics of the solar panel.

In IV results, we want the panel temperature to be 25 degrees. For this reason, there is also a climate sensor inside the IV device. Here, too, the temperature is expected to be close to 25 degrees. The IV device tries to measure itself based on the panel temperature. Even if the panel temperature is 25 degrees, if the environmental conditions are at low degrees, a low power panel can be detected as a result of IV.

Solar Simulator Working Principle

A solar simulator usually includes a lamp, a reflector and an optical system. The reflector is used to focus and diffuse light. The optical system is designed to sample the light and direct it to the target. It is thus possible to simulate sunlight in various conditions and test how certain materials or devices will behave under sunlight.

Reference Cell in Solar Simulator

In solar simulators, the reference cell is a measuring device used to ensure the accuracy and stability of the sunlight produced by the device. This cell has a known electrical output and accurately measures the intensity and spectral distribution of sunlight.

Calibration of reference cells is a very important issue. The reason for this is to accurately adjust the output of the solar simulator device and to obtain reliable results. These cells standardize the performance of photovoltaic devices and enable comparative analysis.

So what are our references when measuring in the Solar Simulator?

Reference Panel in Solar Simulator Devices

There are important considerations in selecting the reference panel used in solar simulators, such as the intensity and spectral distribution of sunlight. The reference panel ensures that the output of the solar simulator is set correctly and is used to ensure the accuracy of the measured data.

What are Gold and Silver panels and why are they used?

In solar simulators, the terms “silver panel” and “gold panel” are often used for calibration standards.

Silver Panel A silver panel is a lower cost version of a standard reference cell or reference panel. It is often used in routine calibration of solar simulators. It is designed to provide the standards used during solar simulation.

Gold Panel Gold panels are more sensitive panels that allow for higher quality control and more accurate measurements. Gold panel is especially preferred in industrial applications that require high precision. These terms are used to refer to the different levels of reference standards used in the calibration of solar simulators.

In order to obtain a healthier result while measuring, there are some points that we should pay attention to in the Solar Simulator device. These are

- Spectral Distribution: The lamps used in the simulator must accurately mimic the spectral distribution of sunlight. This is important to simulate real-world conditions as closely as possible.

- Light Intensity: The light intensity that the simulator can produce should be close to the intensity of real sunlight. This helps to more accurately determine how the panels will perform in real-world conditions.

- Environmental Conditions: The temperature, humidity and other environmental conditions of the environment in which the simulator is used must be under control to ensure that the panels are tested more closely to real-world conditions.

- Calibration The simulator needs to be calibrated regularly. This ensures the reliability of the test results.

- Data Analysis: It is important that the data obtained is analyzed correctly. This is necessary to properly evaluate and improve the performance of the panels.

- Safety Safety precautions must be taken and the simulator must be used appropriately. It is important to use the necessary protective equipment to prevent exposure to light.

Author:

Kardelen Kucuktas