“Soiling” is another issue that should be taken into account when calculating the production of solar power plants. Soiling is based on the effect of meteorological effects such as dusting and snowing on production. We calculate the soiling effect on the panels where we carry out production studies and include it in the production analysis. In this context, we examined the effect of dusting in two different provinces of Turkey far from each other. How much power loss due to dusting? Is washing really necessary? Let us examine it.

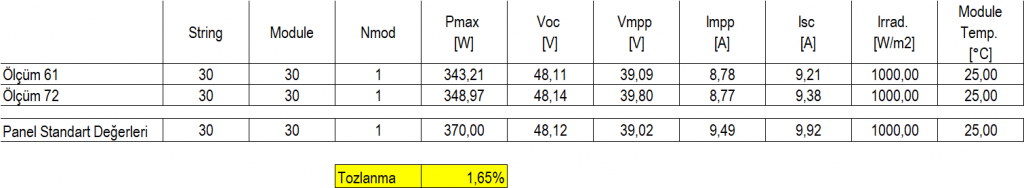

First, let’s look at the results of the test we conducted at our first plant.

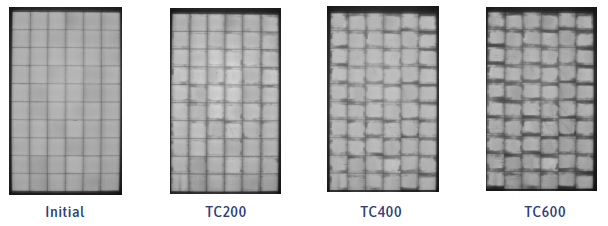

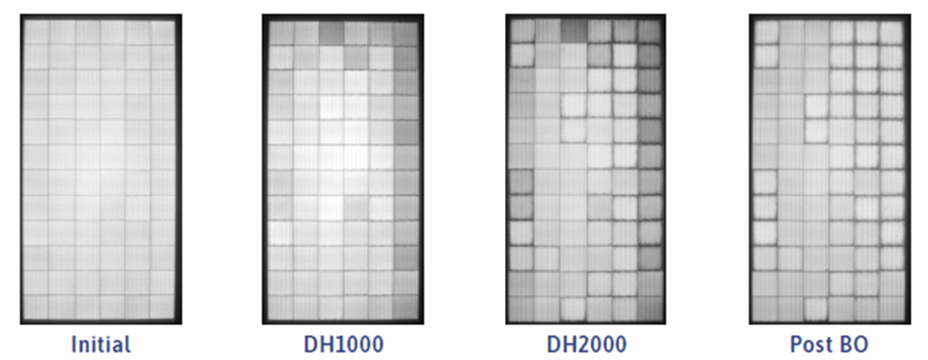

The solar panels were very dusty. We first measured the solar panel when it was dirty, then when it was clean. So what did our measurement results tell us?

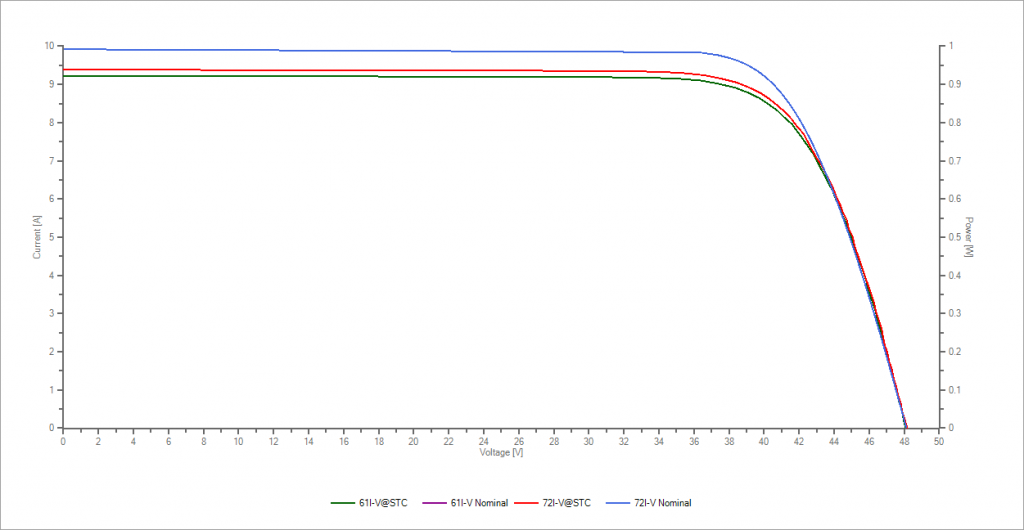

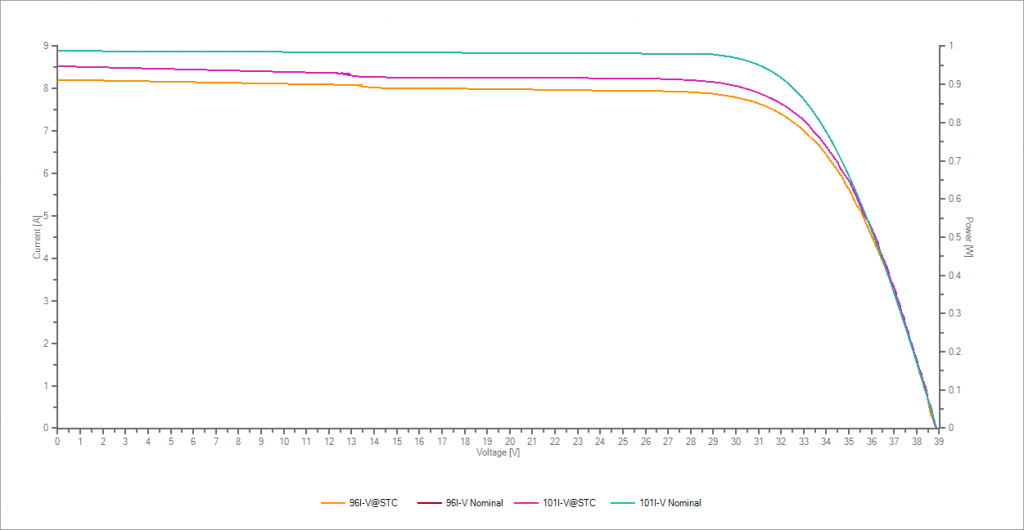

In this graph, the blue line is the IV graph of the solar panel (given in the datasheet). The green line is the measurement with dust and the red line is the measurement after the dust has been removed. The current section (Y-axis) is the part of the solar panel where problems such as degradation or dusting are reflected. The solar panel is not producing the power it should, so how much is this loss? Let us examine it.

In the first measurement we made on the solar panel, which should have a power of 370W, we detected a power around 343W. When we cleaned it later, we observed that this power increased to 349W. The difference between dirty and clean is 1.65%. This is a cleaner facility that receives relatively more rain. But how much impact will it have in a dirtier plant? Now let’s go about 700 kilometers south from the first site.

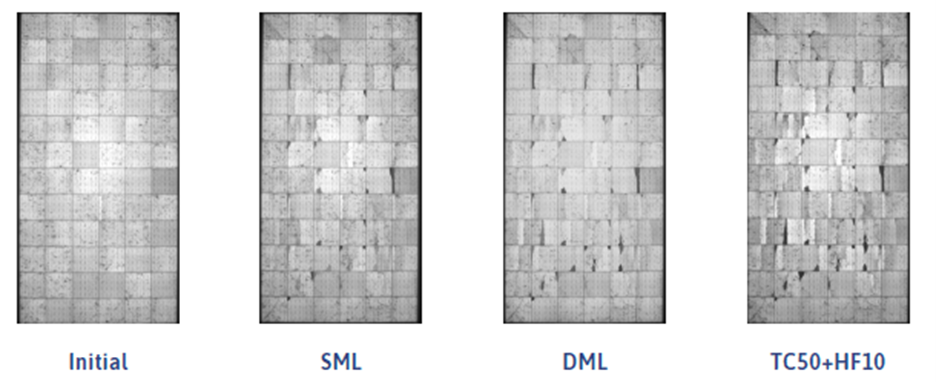

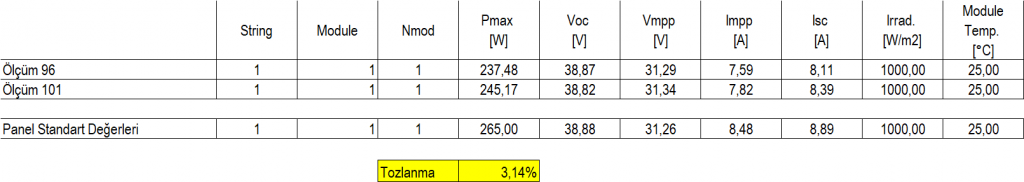

Here the turquoise line is the power of the panel, again based on the data in the datasheet. The orange color is dusty and the pink color is after cleaning. There is also a diode problem / microcrack in the solar panel here (pay attention to the breakage in the graph), but that is not our topic. So what is our numerical data?

Here, when we look at before and after pollination, we see a loss of approximately 3.14%. If this pollination continues until the end of the year, our annual production will drop by 3.14%.

It is not correct to say that the annual impact of dusting will be 3.14% directly. When it rains, the dust is washed away (sometimes it can sediment, but most of the time it is cleaned) or factors that damage the panel, such as bird droppings, may remain. Therefore, this value will change. Here we have not examined a SPP next to a facility that regularly generates dust, such as a cement plant/quarry. If you are near a facility that regularly generates dust, this figure is likely to be slightly higher.

In Turkey, a 1MWp ges plant generates between ~1,500MWh and ~1,600MWh per year. According to the distribution fee (before and after 2018), it generates an annual income between approximately 160.00USD and 200.000USD.

For an investor with a 1.65% annual dusting loss, the loss would be between 2,500USD – 3,000USD, while for an investor with a 3.14% dusting loss it would be between 5,000USD – 6,200USD. Solar panels shed some dust with every rain, but dust can also settle in some spots. Probably the annual average of these values will be lower than what we have calculated, but an investor with a 1MW ges can expect an annual income loss between 2.500USD – 5.000USD due to dusting.

In my opinion, the main point of washing the solar panels is to extend the life of the panels by cleaning the parts that can create hot-spots such as bird droppings on them, since only dusting does not damage your panels.

The danger of the washing process is panel breakage. In flat areas, cleaning can generally be done without breaking the solar panel, while in sloping areas, some machines can break the panel or washing machines can damage the panel surface. When the panel breaks, the whole advantage of this work is gone.

People who want to benefit from this service should examine the cost and production increase of the washing process and the risks such as the risk of breaking the panels or damaging their surfaces. Be sure to pay attention to whether the equipment used by the company you will have your solar panels washed has a certification and whether the cleaning material (detergent, etc.) to be used is suitable for this job. You don’t want to make too many eyes.

If we mention the deficiencies in the facilities we inspected in order of importance, 1) Monitoring system, 2) Cleaning of plants and 3) We can list it as dusting. If you pay attention to these issues, your facility will last longer.

Email : [email protected]