Both the experience gained by the solar energy sector representatives in our country and the increase in the price/performance ratio of the products used show that the solar energy sector is a reliable energy source for our country. However, with the new investment options planned by the Ministry of Energy (Mini Yeka), it is no longer possible to realize the old ROIC rates. This situation makes high-level engineering work essential for new investments, and the slightest design change in the projects changes the feasibility studies. As Solarian, we offer the most accurate and detailed engineering services to our investors at this stage.

In solar power plant investments, connection power and land boundary are parameters that cannot be changed. These parameters determine the design criteria of each project and the differences between them create the character of the power plant. The considerations to be taken into account when designing each project are different. Let us examine these issues in more detail below.

1 – Technology Selection and Installable Capacity Study

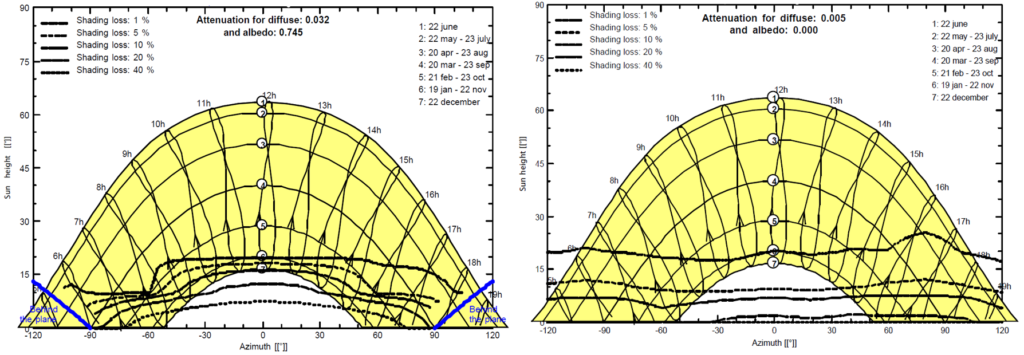

First of all, a maximum installable capacity study should be conducted for the project site of the solar power plant using different technologies. Analyses such as the surface condition of the land, the effect of the surrounding hills on the horizon line, shading study constitute the steps of this study. These analyses should be carried out in detail because it is the use of the most appropriate technologies that improves plant performance, not the latest technologies.

For example, the study on the left below shows the hourly shadow ratio of a power plant with a fixed-angle construction and the study on the right shows the shadow ratio of a power plant with a north-south axis monitoring system according to the shading distance and tilt angle throughout the year. As can be seen, although the fixed-angle system is subjected to short-term shadowing at sunrise and sunset, the tracking system experiences this situation throughout the year. This leads to loss of production.

2 – Creating Climate Data Set and Production Profile

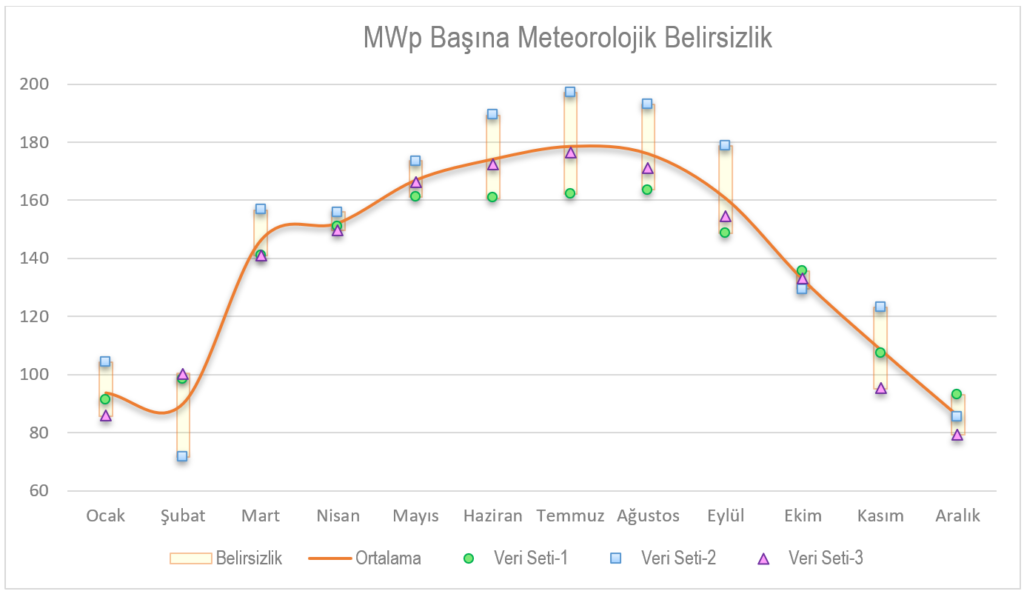

Each power plant has its own production profile. Since this profile is shaped by irradiance and temperature values together with the technical analysis above, it is necessary to create a good climate data set. Each deviation in climate data directly affects production. This indirectly affects the project return. Identifying potential deviations while creating the climate data set will ensure project cash flow control.

For example; the graph below shows the monthly production deviation values prepared using 3 different meteorological data sets and tells us that there may be an annual deviation of 4.2% in production data. Thanks to this study, by analyzing the possible monthly deviation rate of the production profile, the loan payment maturity plan or cash flow analysis is made healthy.

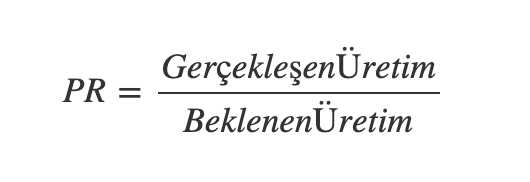

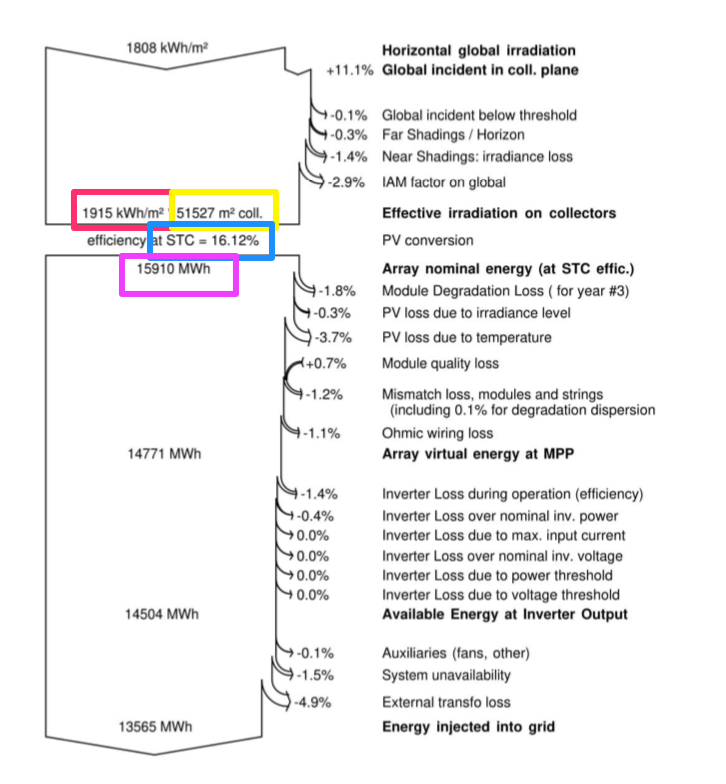

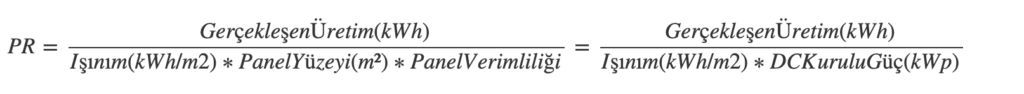

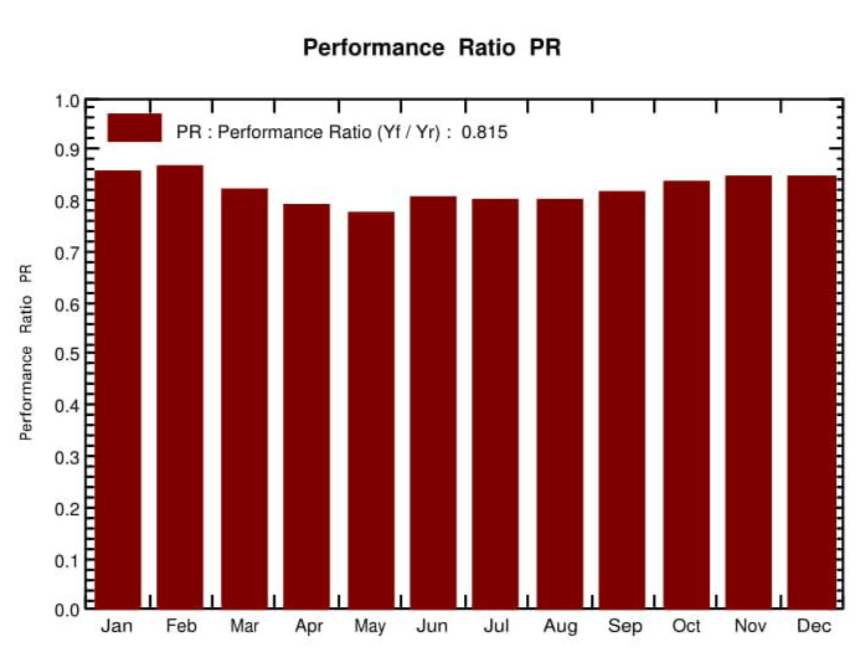

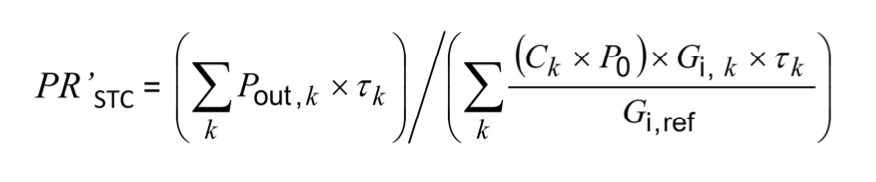

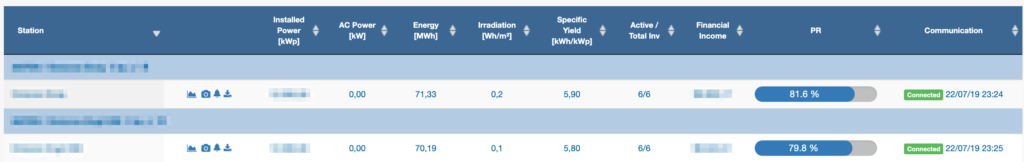

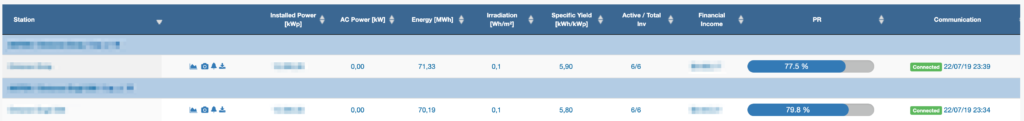

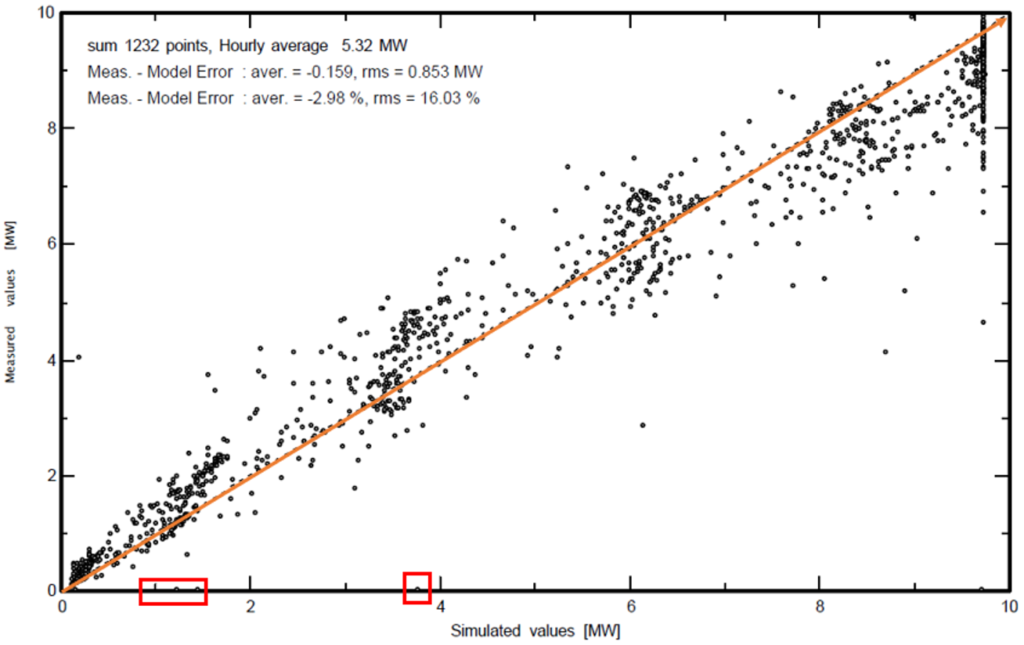

3 – Performance Ratio (PR) and Availability Ratio (Availability Ratio) Calculation

Another important issue is the calculation of the performance ratio (PR) of the power plants. This is because the operation and maintenance companies take over the plants that are put into operation, provided that they meet a certain performance ratio. At this stage, it is necessary to apply the correct performance ratio calculation methodology in order to be able to make an opinion about power plant performance and operation and maintenance quality. In a previous article, we explained the correct methodology for calculating PR (you can find the article here ).

Considering solar power plants as a 25-year investment, the availability and performance ratio calculation during the operation process is very important and should be checked periodically. In this way, areas of the power plant that do not perform as expected are identified and necessary interventions are made before the loss grows.

The study below shows the PR verification of the commissioned power plant over a certain period of time (3 months in this graph). The hours below the orange arrow symbolize lower than expected performance, while the hours above symbolize high performance. The hours in the red box give us information about usability.

All the analyses mentioned above require detailed engineering work. Good preparation of the project will make the investment efficient and reduce the cost of financing. Solarian provides long-term support to investors as a reliable technical consultant at all the above stages. If you want to own a power plant with high added value and high profitability, contact us.