It’s time to build a solar power plant and generate your own electricity. In this process, with our employer engineering service, we technically manage the entire process for you and help you get the best out of the facility you will build.

You can find our technical engineering service scope for SPPs below. If you have any questions about our scope of services, you can contact us here or send us an email.

1. Pre-Construction Period

1.1. Design Selection and Yield Analysis

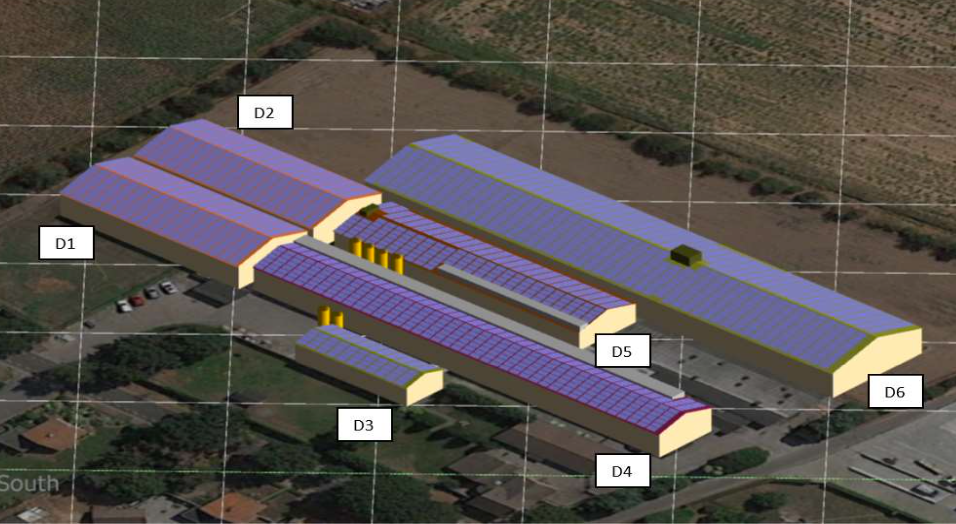

Optimum shading distances, angle values, dead zones and the associated potential installed power values are determined based on the structure of the roof or terrain.

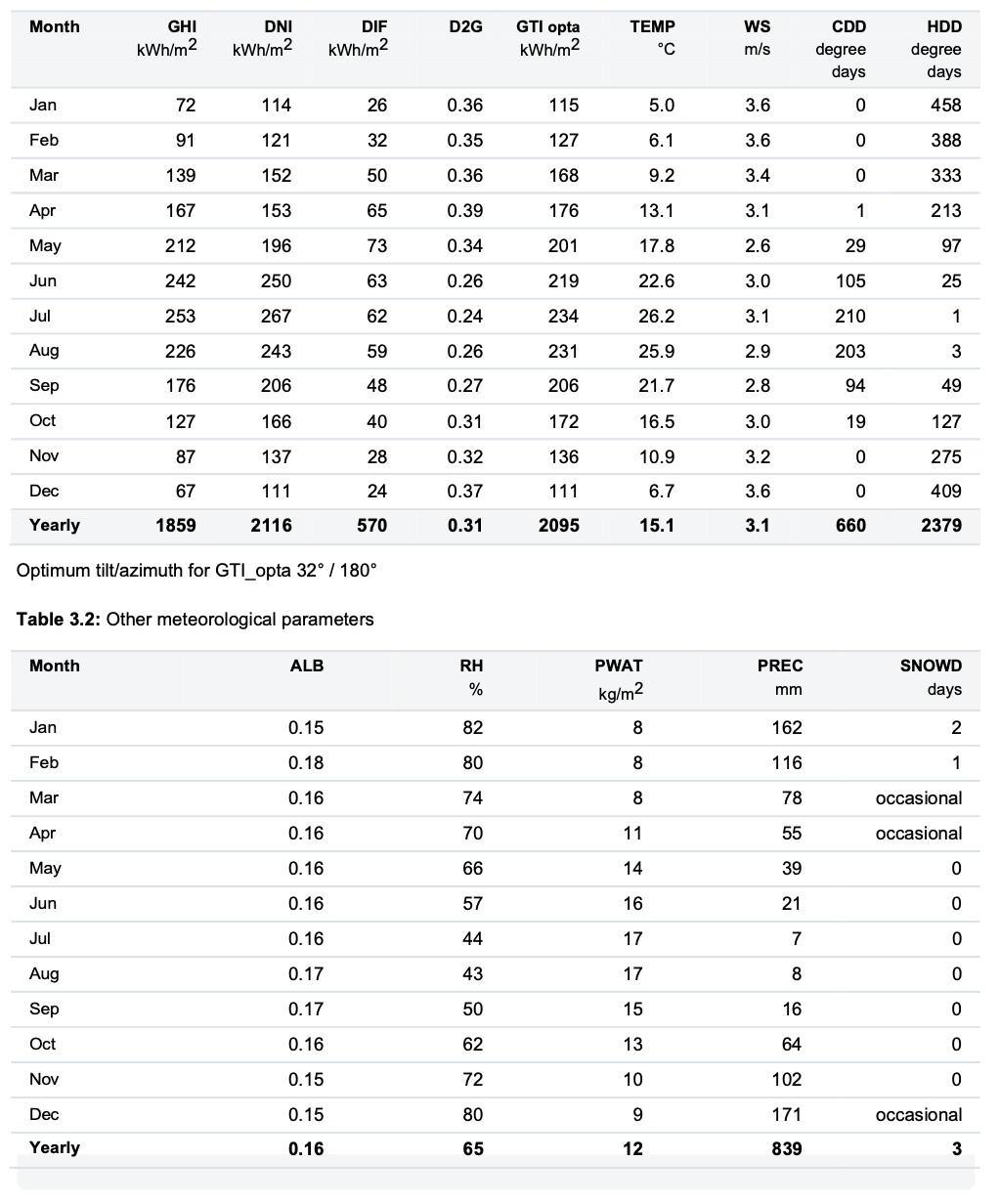

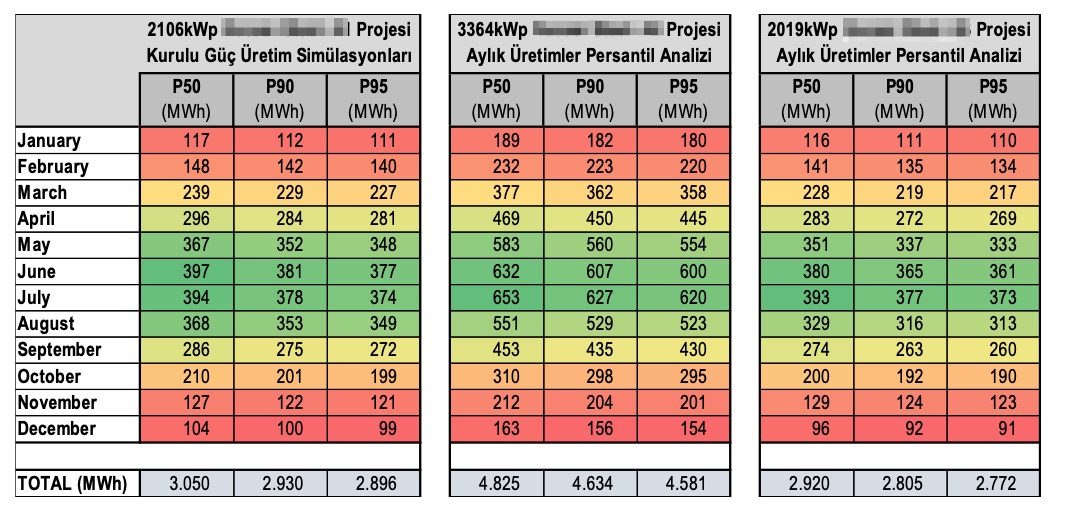

The meteorological data set (radiation, temperature, etc.) required for SPP generation analysis is compiled. In order to create the data as close to reality as possible, 4 different data sets are utilized and sensitivity analysis is performed.

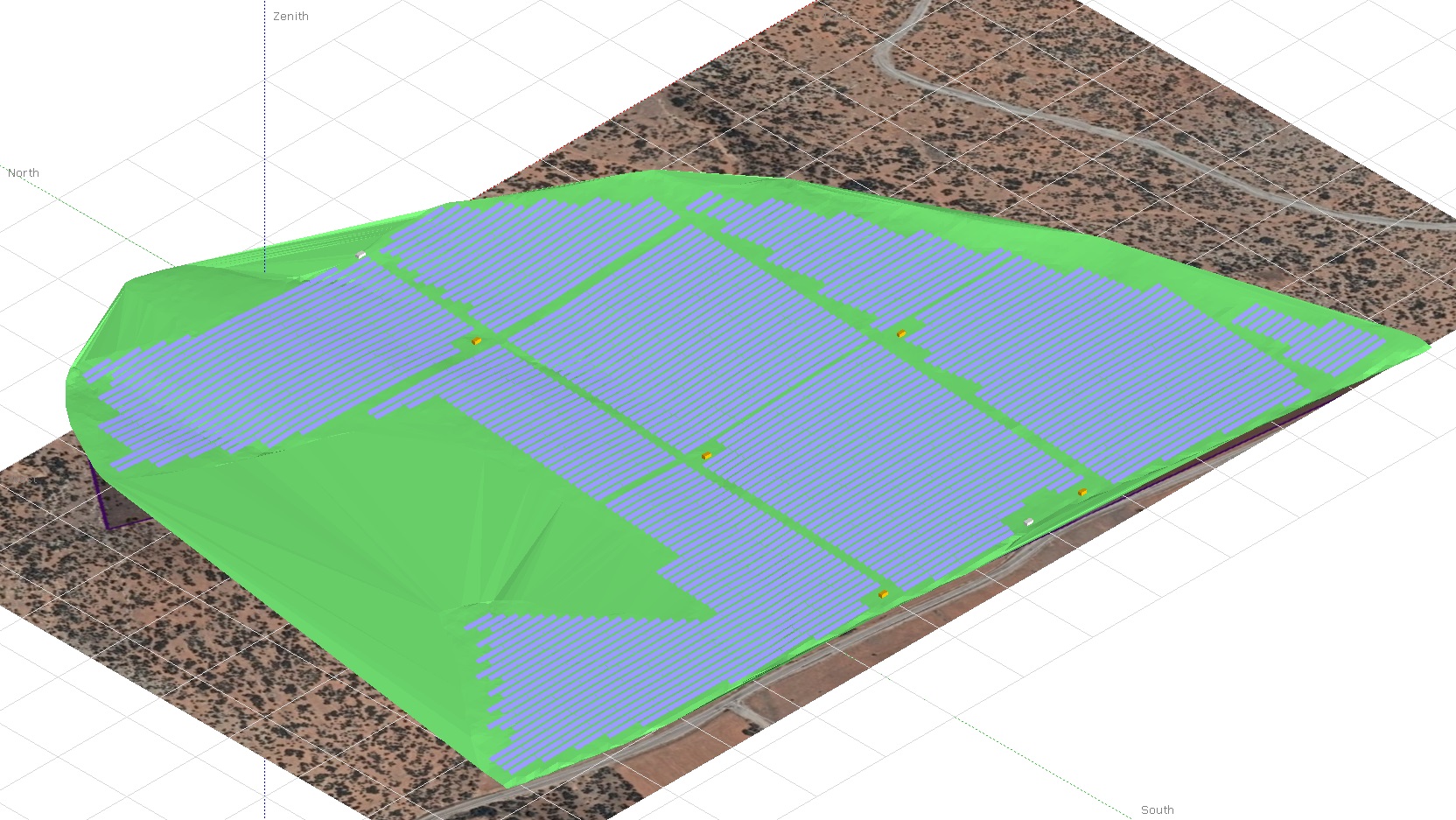

The biggest loss factor in rooftop SPPs is shading and shading analysis needs to be performed in detail. At this stage, we calculate shading losses by drawing both the obstacles on the roof (chimney, lighting, etc.) and geographical obstacles (mountain, tree, etc.) in 3D. Even in the same region, shading may vary according to the structure of the surrounding land. Since these will have a direct impact on production, their analysis should be done professionally.

The equipment used in solar energy facilities (solar panels, inverters, etc.) vary technologically. These different technologies are evaluated and appropriate installed power values and design are analyzed.

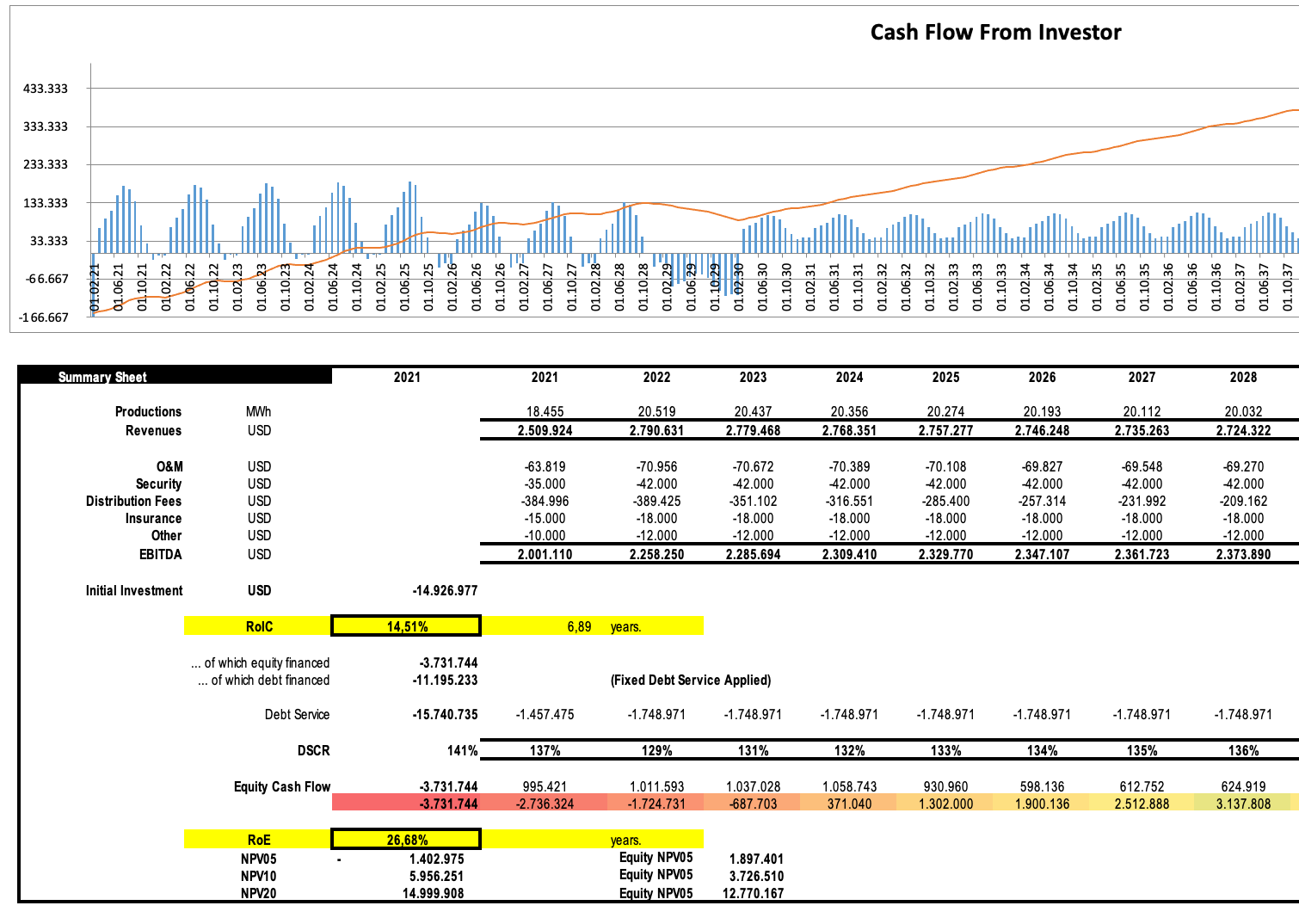

1.2. Financial Feasibility Study

A financial model that works in harmony with technical inputs is a strategic decision support tool for investments. In this respect, cost analysis is performed for all design alternatives. Bids received from EPC companies are included in the cost analysis and a project-specific financial feasibility model is built. Internal Rate of Return (IRR) and Net Present Value (NPV) results are calculated by running the model and reported to the Employer.

1.3. Control of Conformity of Technical Documents to Relevant Standards

Technical specifications are very important for a flawless installation application. After the project design studies are finalized, the compliance of the EPC and O&M technical specifications with the relevant standards for the SPP project is checked. It also clarifies the methodology to be used in calculating the project’s PR.

1.4. Approval of Final Projects

After the selection of the EPC, the projects to be drawn by the EPC are controlled and approved by us, and the approval of the projects by the EPC to the relevant institutions is supervised.

2nd Construction Period

Construction period engineering services are the processes that include the design and supervision of the processes that will take place during the investor company’s solar power plant investment and the commissioning of the power plant. In this way, it is aimed to minimize the risks and prevent possible problems that may occur in the long term. It also aims to take measures to protect the rights of the investor for possible legal processes.

2.1. Determination of Technical Quality Criteria with Reference to Relevant Standards

First, a SPP project kick-off meeting is held and a construction roadmap is created. At the same time, a responsibility matrix is created to prevent problems that may arise in the later stages of the project.

Contractor requests arising from problems that arise during implementation are examined. The technical compliance of these requests is checked and communicated to the investor, facilitating decision-making processes.

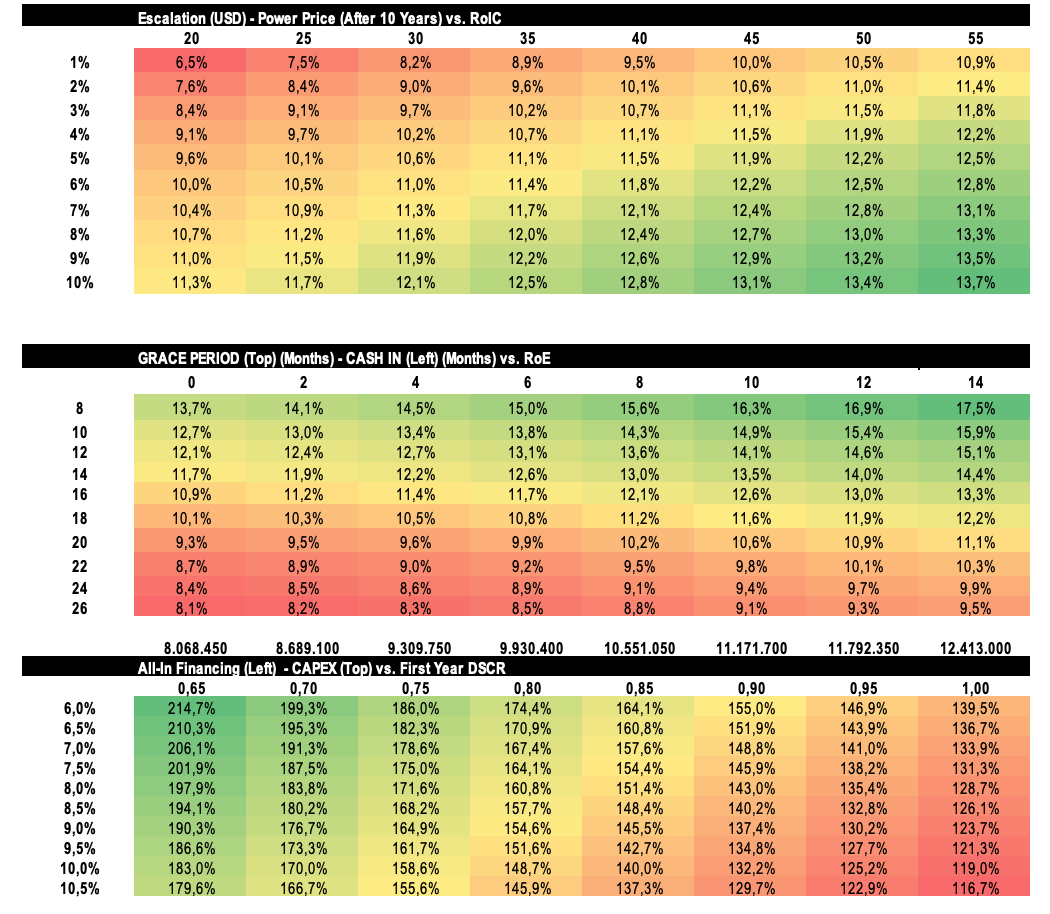

2.2 Solar Panel Production Process Factory Inspections

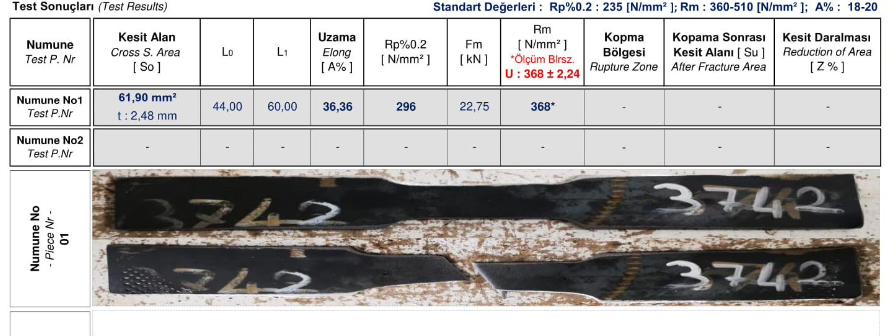

The most important equipment used in solar power plants is the solar panel. For this reason, it is important that its production is realized in accordance with the standards. Production controls of solar panels are carried out in two stages. At the first stage, product certification control is carried out. Factory inspections are then carried out during the production process. 2.3. Inspection of Construction Processes

2.3. Inspection of Construction Processes

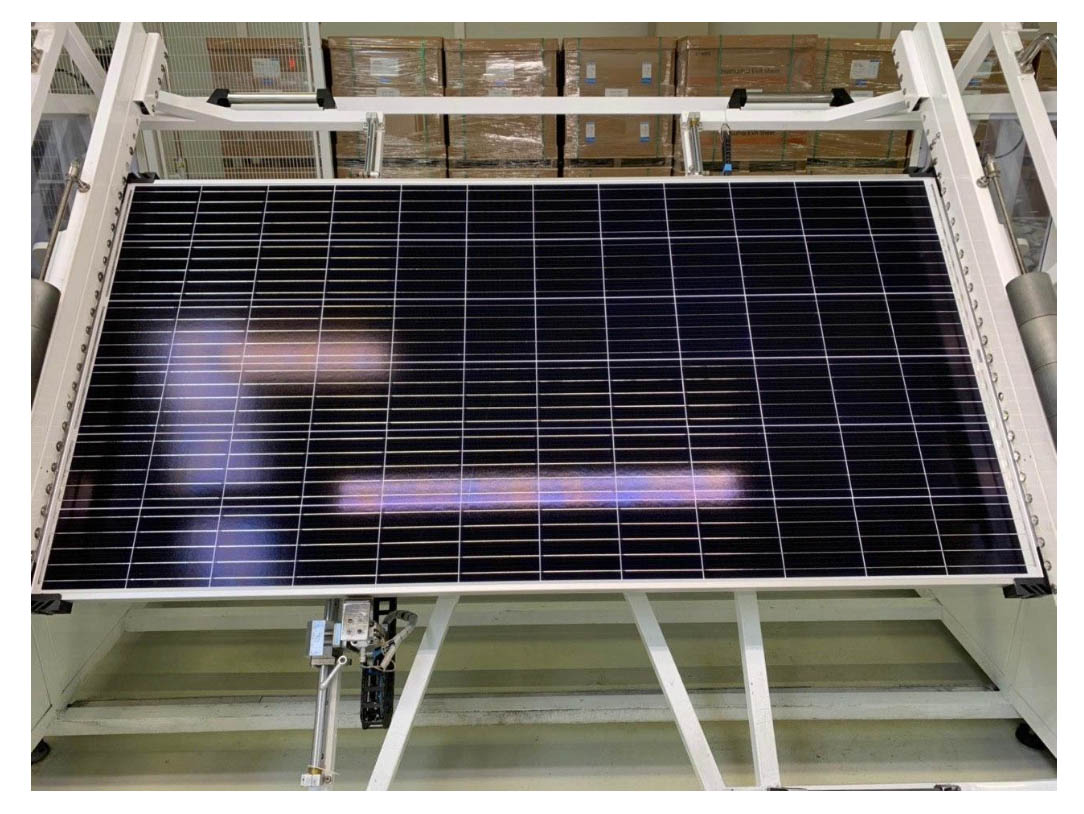

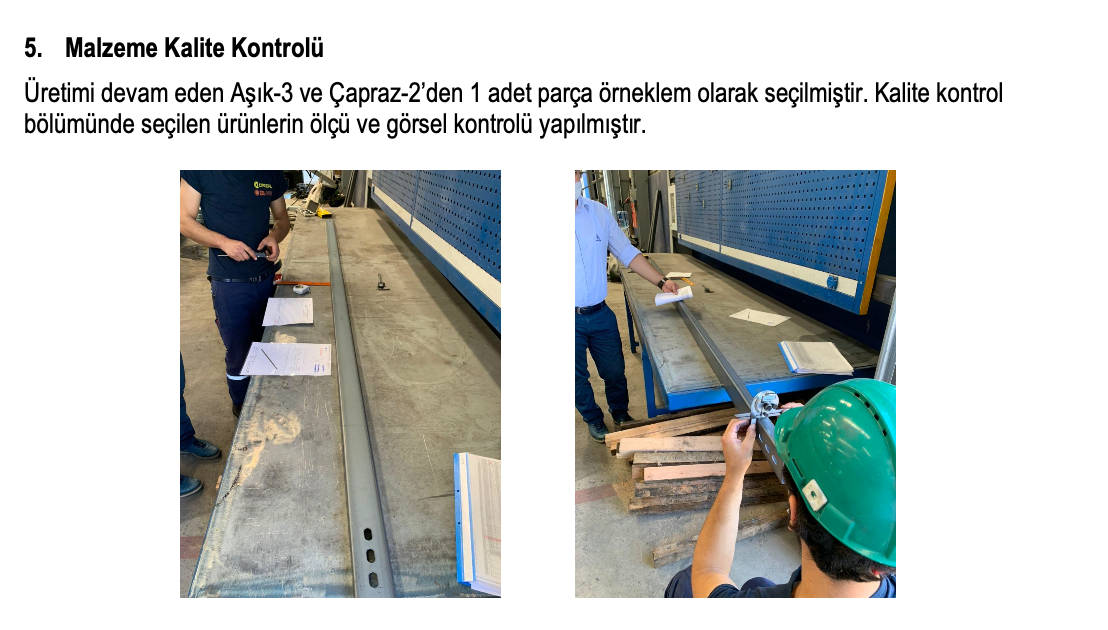

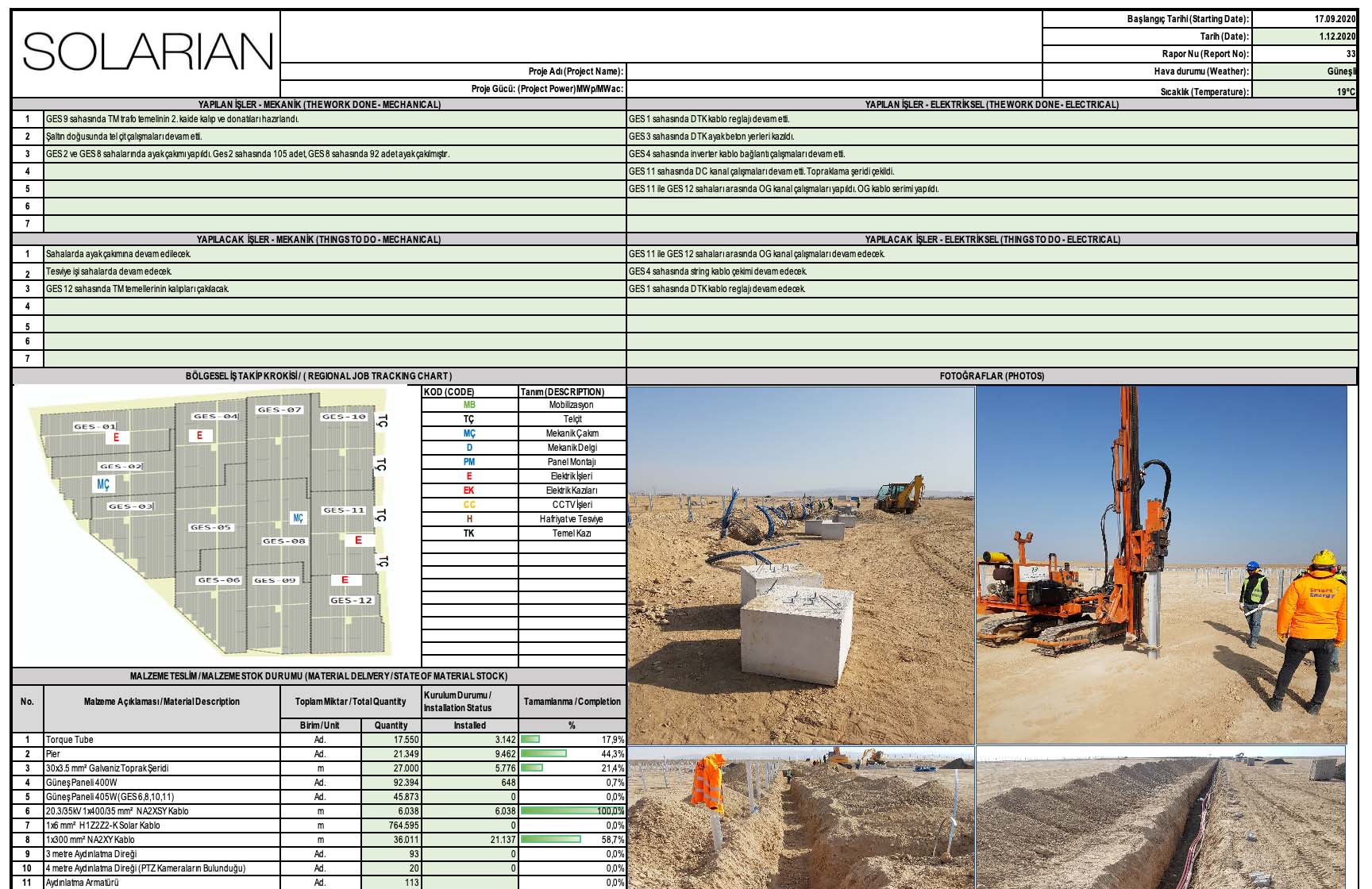

Regular on-site project audits are carried out for the healthy progress of the project from inception to acceptance. In this process, project progress is monitored according to the contract. Regular project visits are carried out during construction. According to the requirements of the EPC contract, construction and project progress is monitored in line with the planned schedule.

Quality controls are carried out during the production of incoming materials for the SPP plant and after shipment to the site.

All construction and assembly works are carried out in a controlled manner, as any mistake in the assembly part may become irreversible in the future. The process is regularly reported and recorded from start to finish.

2.4. Commissioning Tests

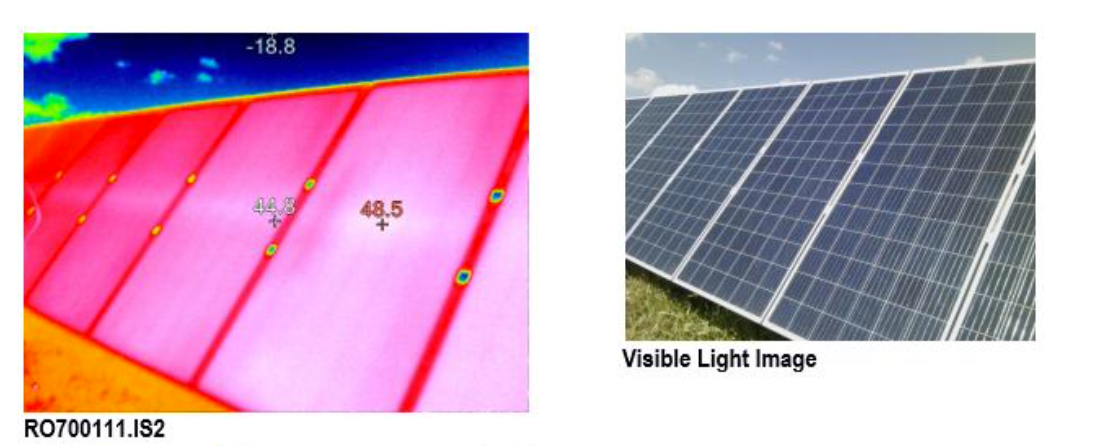

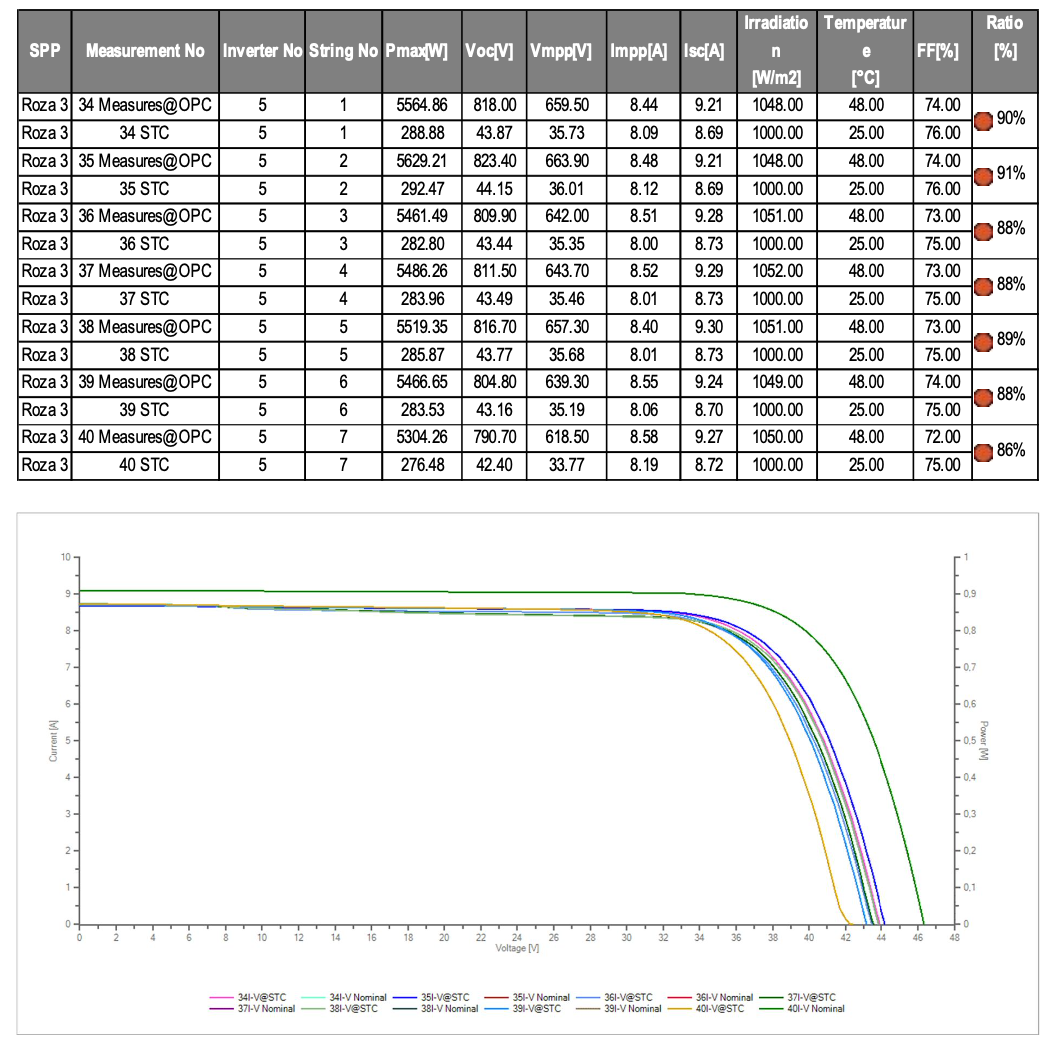

In order to monitor and measure the performance of solar power plants, it is necessary to perform tests within the scope of IEC 62446 and IEC 60891. These tests are mainly IV-Curve (current-voltage) measurement, thermal tests, insulation test, grounding test and performance measurement. After the solar power plant is installed, these tests are carried out and it is analyzed whether the plant performs as expected. You can find a detailed description of the tests here.

A report containing all the tests is prepared. This report is also a risk table. According to the report, the findings are prioritized and presented to the EPC company. Warranty processes are put in place and a new business plan is created together with the EPC company to meet the necessary conditions.

3. Final Acceptance Tests (IEC 62446)

After at least 6 months of operation of the facility, a site visit is made and visual and electrical controls are carried out according to the standards. At the same time, performance measurements of the equipment are made and it is reported to the investor whether the conditions guaranteed by the manufacturer are met. Visual inspections check for physical defects, while electrical tests check production performance.

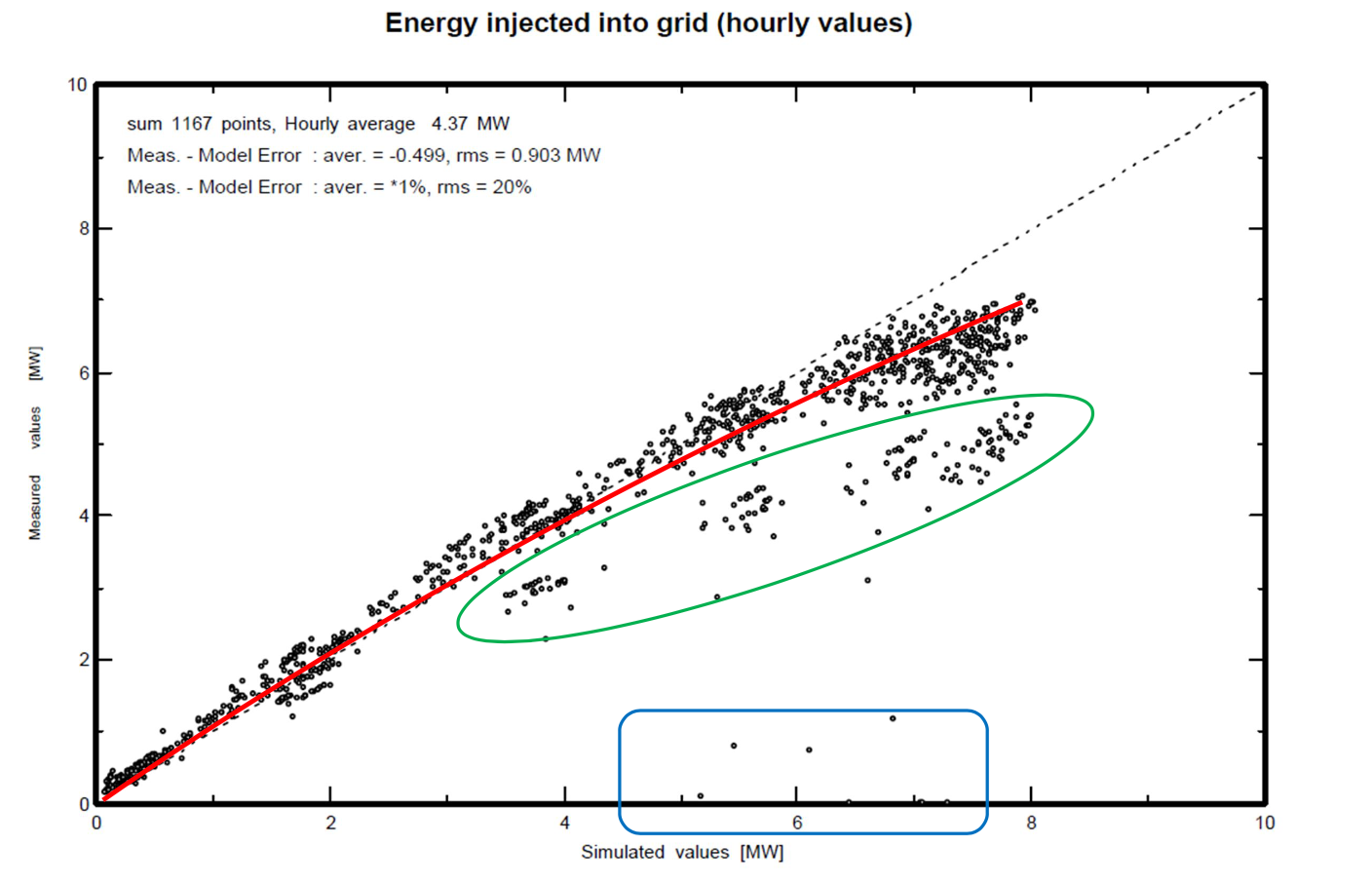

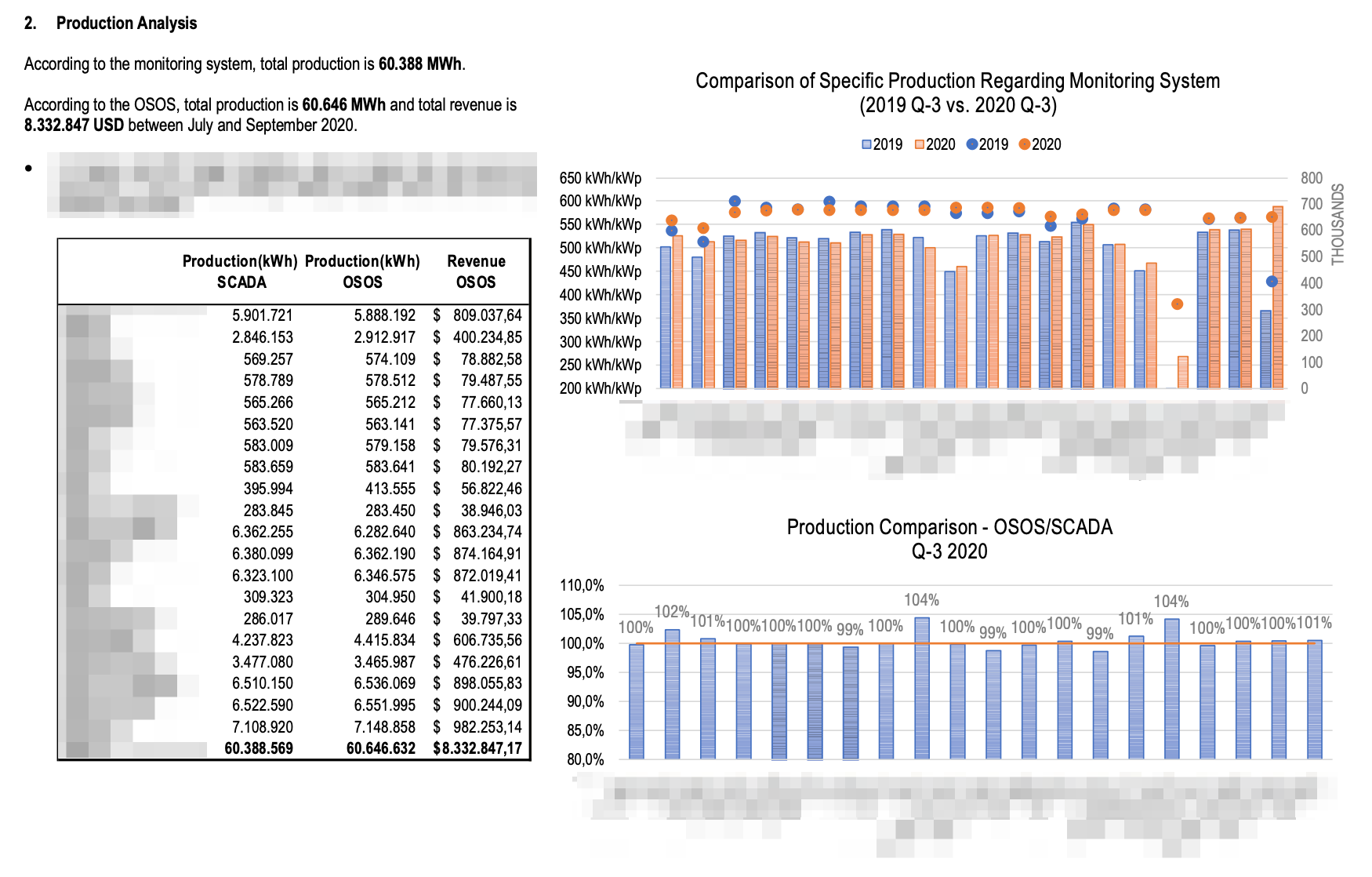

Once the plant is in production, radiation data, production data and temperature data are processed and the overall efficiency of the system is calculated. With this calculation, the performance of the system is revealed. In the subsequent controls, degradation is also based on this data. This is a necessary data set to track any project-wide problem or excessive degradation of cells.

4. Monthly Operating Reports (For 12 Months)

Once the plant is in production, radiation data, production data and temperature data are processed and the overall efficiency of the system is calculated. With this calculation, the performance of the system is revealed.

We are with you as your engineering team in the entire process from system design to operation.

Please contact us for information about our employer engineering service.