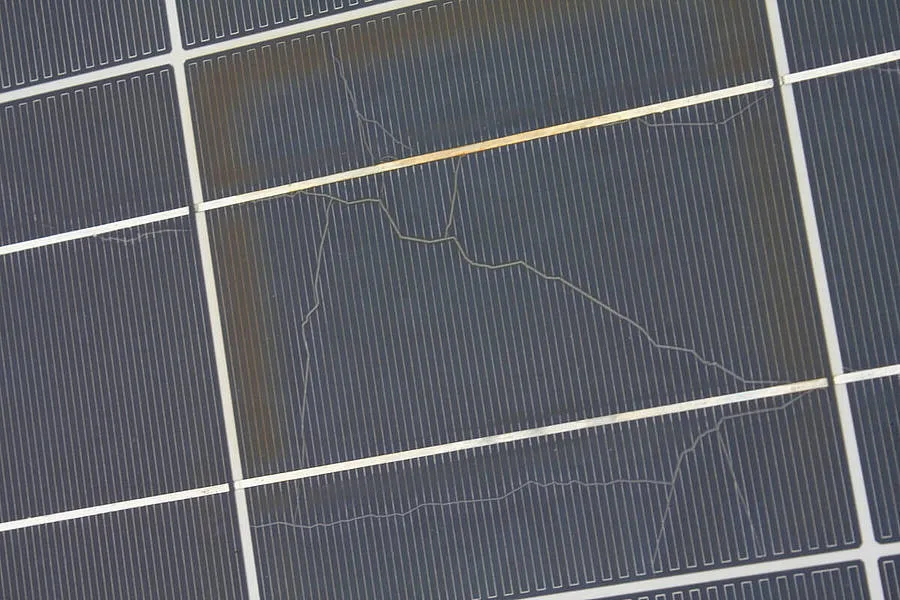

Photovoltaic modules are very thin systems. The materials used must be subjected to detailed inspections after a careful production line process to avoid human or machine-induced damage.

The materials of solar cells often show dark spots and fracture problems at the corners and edges.

Broken corners often occur at the edges and corners of the solar cell panel, often related to damage from collisions. Often, incoming materials enter the production process without being checked or verified, resulting in defective products and production losses.

The process to be carried out for corner and edge collapse is to strictly screen the incoming materials and send them back to the manufacturer when defects are detected.

Dark films and broken gratings are usually caused by raw materials. Dark films cause internal damage, leading to confusion in the power range. Broken gratings can occur during the production or transportation process.

We should not underestimate problems such as dark films and broken grids. It is important not to mix power levels during the production process, especially when replacing single cells.

It is also important to strengthen the inspection of incoming materials, increase the sampling rate and timely notify the supplier of any problems detected.