By installing an off-grid system, you can generate your home’s electricity entirely from the sun. Of course, before installing your system, you should evaluate your energy consumption habits and determine the number of solar panels you will use in the light of these.

Besides solar panels, your off-grid system also needs batteries to store the energy you produce.

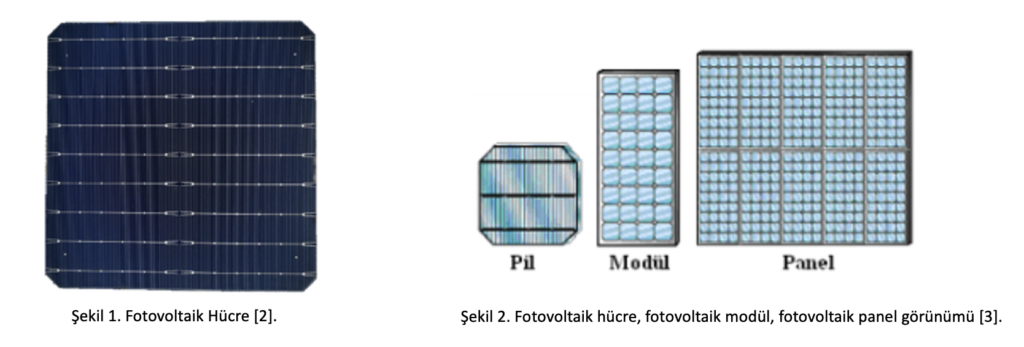

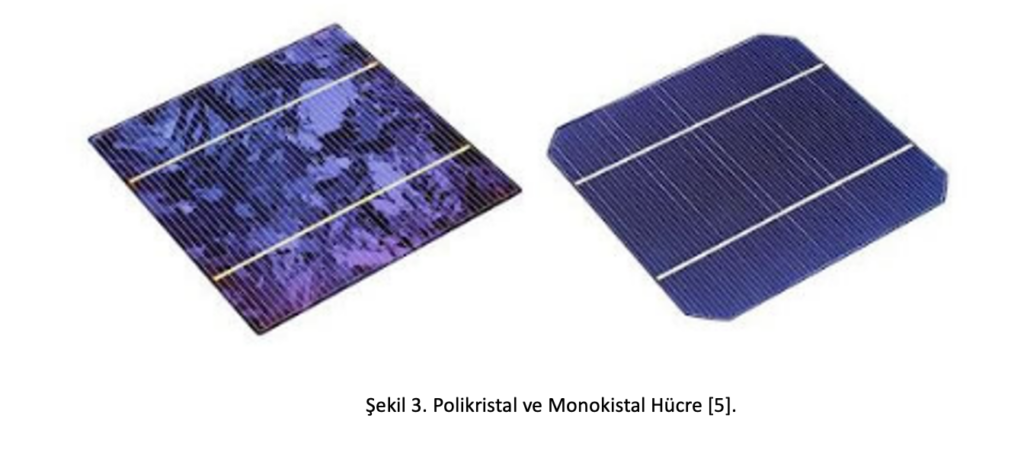

As for how big the freestanding system should be, it depends on how much electricity your home needs, how much free space you have on your roof space, how much direct sunlight the solar panels receive each day, and the type of solar panel you choose.

On average, your home will require a 7 kW solar system if you want your whole family to depend on solar energy. Please note that you can find solar panels in different sizes and shapes. There are also DIY kits available for purchase.

In addition, there is also a publicly connected solar system, which, when publicly connected, connects to the public grid and generates electricity. In this case you don’t have to rely on batteries or battery packs to store energy.

Now, the performance of solar panels is usually determined under standardized test conditions (STC). Generally, larger solar panels provide higher performance. For example, if your home requires 7 kW and you need 200 watt solar panels, you will need at least 35 panels to meet your energy needs.

If the solar system is 10 kW, at least 52 solar panels are required. Likewise, for a 20 kW scale solar system, the best option is to use 105 solar panels (positive or negative).

The following basic formula will help you understand the number of solar panels needed on your home.

- Step 1: Get your latest electricity bill. Now, check how much energy your home consumes. Energy consumption will be shown in kWh. This is the energy used.

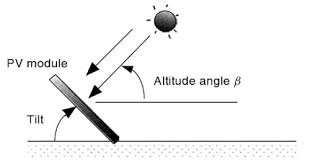

- Step 2: After completing Step 1, calculate the hours when your roof receives enough solar energy. This is when the solar panels are at their highest efficiency. If you live in a place with enough sunlight, there is no need to look for a larger solar system.

On the other hand, if you live in a place with less sunlight, your home will need more solar panels. The important thing is to generate enough energy from the solar panels and provide the best electricity for your home. Average peak hours of sunlight usually reach 1000W/square meter.

- Step 3: Calculate the hours of available sunlight or solar energy you received in a month. Now multiply the hours by 30. Whatever you get, you must divide it by 1000 kWh.

For example, if you assume a peak sunshine duration of 5.44 hours, you multiply it by 30 and you get 163.2. Round the number to 163 and divide by 1000 and you get 6.1. Now, this 6.1 is the amount of kW of solar system your home needs.

- Step 4: Multiply the resulting number by 1000 and you will get 6100 watts. Suppose you want to buy a 200 watt solar panel system. Now divide 6100 by 200 and you get 31. Therefore, the number of solar panels you need is 31. In this way you can calculate the size of the solar system and the number of solar panels needed.