Our experience in solar panel production/inspection has exceeded 10 years this year. From the production of components used in solar panels to the degradation of solar panels, 10 years full of analysis and studies.

One of the consultancy works we currently carry out is the inspection of the solar panel factory during the production phase. There are many issues we pay attention to, from the dot-comma in the certification documents to the psychology of the laminator operator, which is the only way to ensure proper production in some manufacturers.

(Note: Of course, there are factories that produce very good products without being inspected; I exempt them).

What about those who buy solar panels online for their small off-grid system, for their boat, for their hobby project? What are they really buying? I was curious; I went and bought them.

That’s the explanation. 20W solar panel; poly crystalline. After placing the order, I started to wait with great excitement; I wondered what would come?

By the way; 150,66TL including VAT. It comes to approximately 127TL. That corresponds to 18,26USD. If we say /20, I pay 0.92USD/Wp, which is around 0.25USD/Wp for solar panels today.

Anyway, time passed, after struggling with the carriers, I received the cargo in these COVID days.

Our first topic is visual inspection

Visually, it’s bad. So how many watts is this panel that I bought as 20W?

I immediately set up the test rig on the roof of the office.

First I connect the cables. It doesn’t come with a cable.

Then I set up the test rig on our roof and reach through the window and place the test rig on the sloping ground next to us.

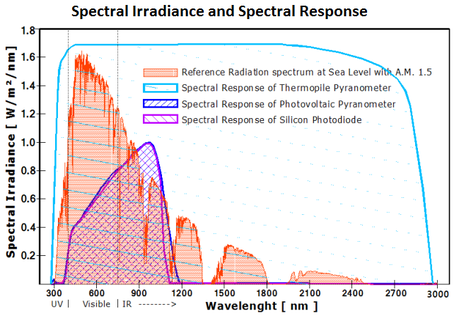

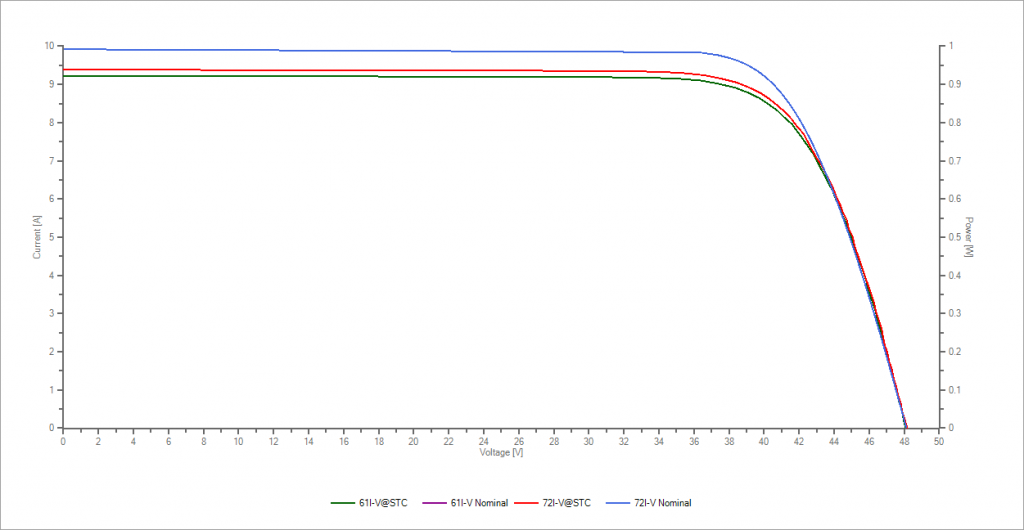

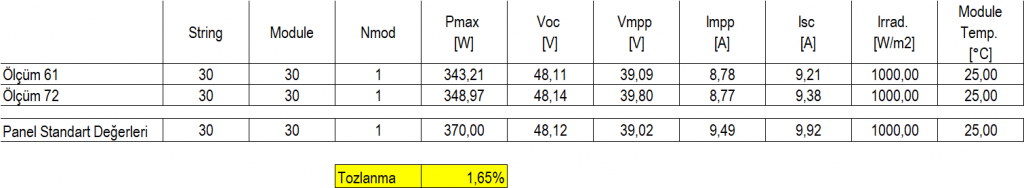

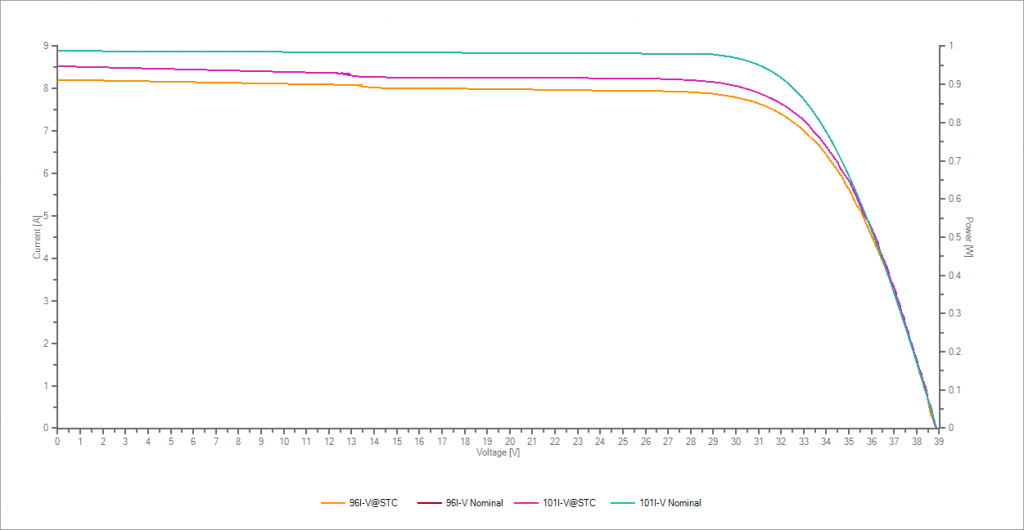

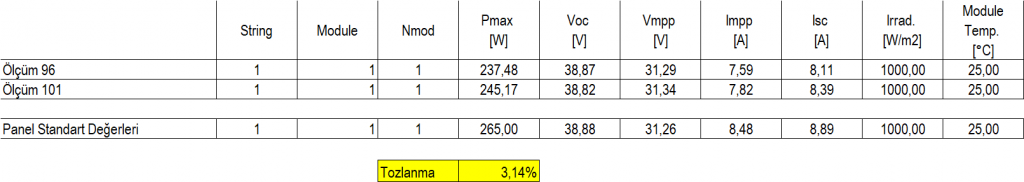

Our panel is ready for testing. I immediately perform IV measurements. I have a radiation of 966 w/m2. The ambient temperature is around 25 degrees. OPC conditions are very close to STC.

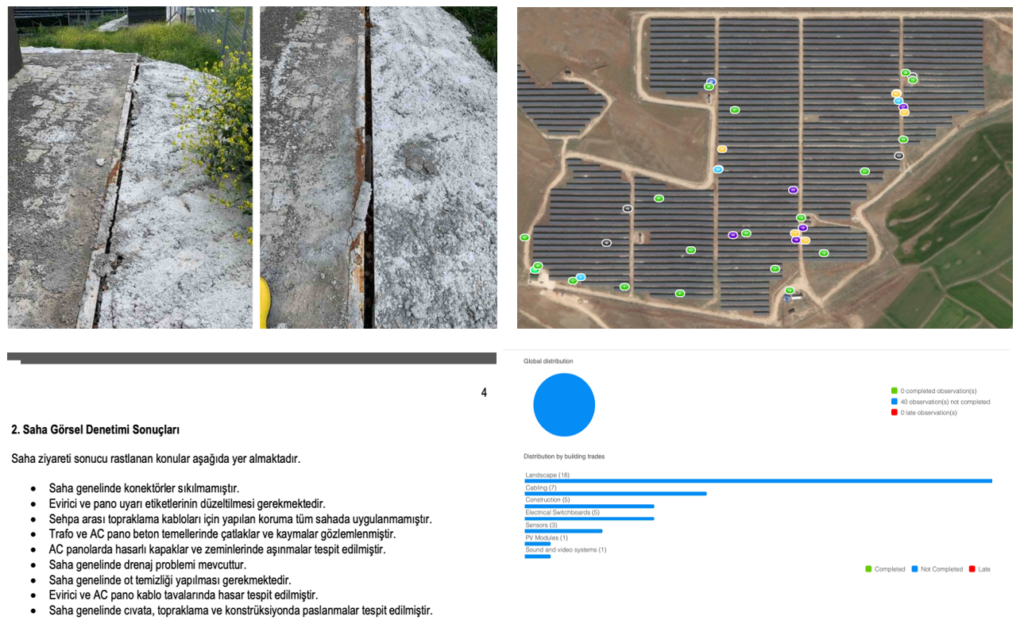

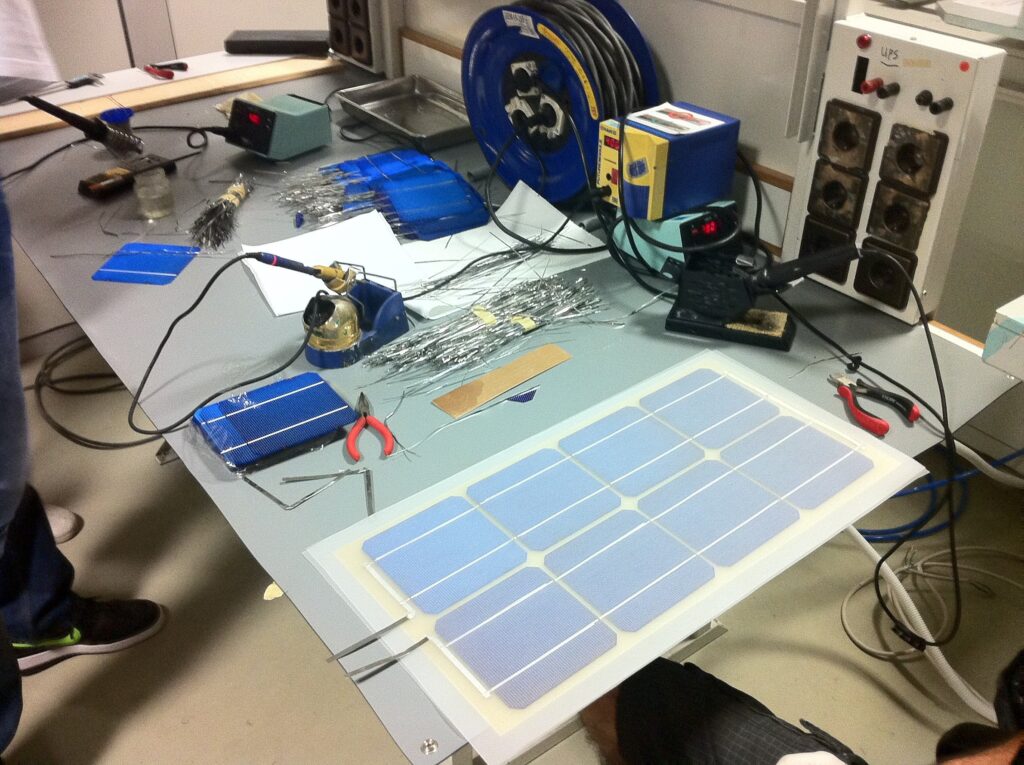

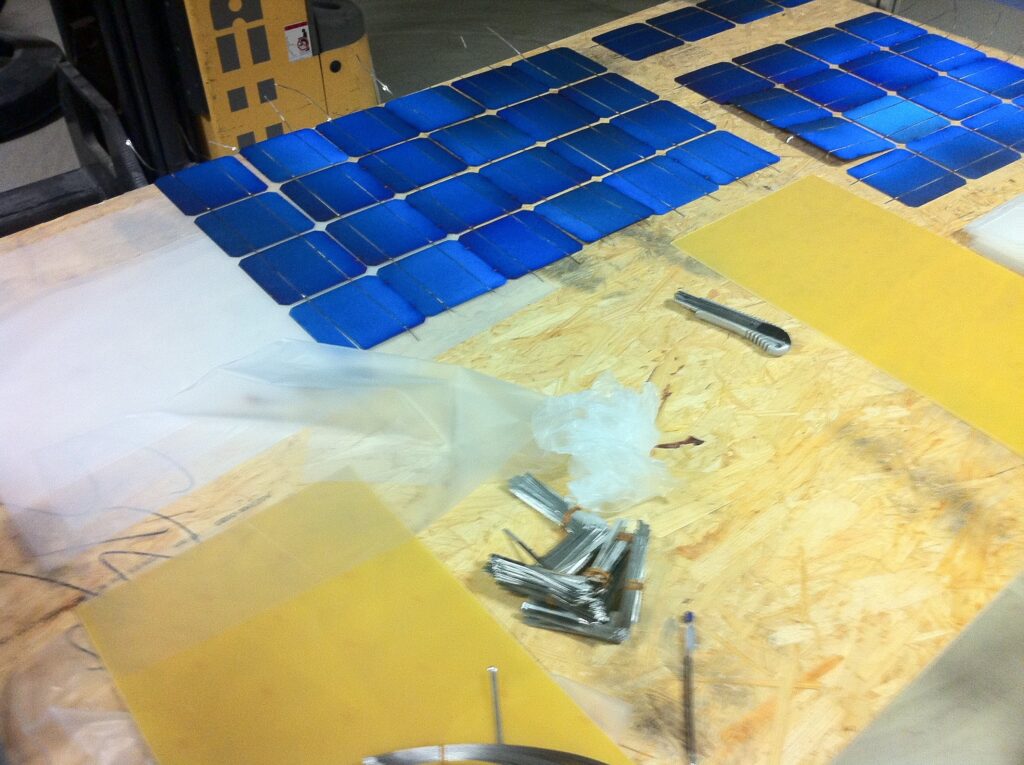

Before moving on to the IV measurement results, let me share a photo of a situation we encountered in a place where we went for inspection.

You may think that your product is made on German-made stringers and laminators, but sometimes this is not the case at all. Sometimes they solder cells with a soldering iron on the table.

Anyway, let’s get to the IV test 🙂

I have measured the solar panel 4-5 times in a row, each time around 16W. This is the OPC measurement value. When I convert it to STC, it corresponds to around 16.4W. In other words, our panel is actually not 20W, and I would be very surprised if it was 20W.

But how good are the cells? Let’s do a quick EL test in the office.

Fractures, areas that do not pass enough current, etc. Considering that this product will quickly enter LID degradation, it will drop to 12W levels soon after you start using it.

I couldn’t do a thermal test because I need to pass current through it in order to do a thermal test and I don’t plan to use this panel as a generator.

To summarize; if you buy a panel online, you may not find what you expect.

If you have any questions about your solar panel, you can contact us below.

Email : [email protected]