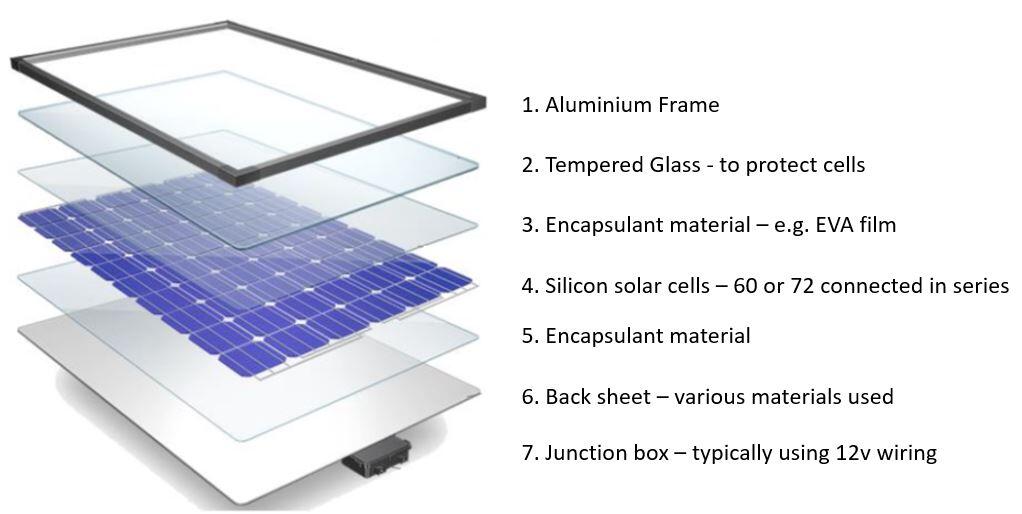

Although the materials of construction of photovoltaic power generation systems vary, all solar modules contain several layers of materials, from the surface to the backlighting surface. Sunlight first passes through a protective layer (usually glass) and then enters the solar cell through a transparent contact layer.

At the center of the solar module is the absorbing material that absorbs photons and completes the “photo-generated current”. Among them, semiconductor materials vary depending on the specific photovoltaic system requirements, and photovoltaic modules are mostly composed of seven main materials.

1. Aluminum alloy frame

Protects glass edges; Aluminum alloy is combined with silicone clamping, improving the sealing performance of solar modules; Greatly improves the overall mechanical durability of solar modules, Facilitates the installation and transportation of solar modules,

The connection carrier, which carries and supports the solar modules, ensures optimal load-bearing capacity from unit fixing to integration, improving the mechanical capacity of the power plant system.

2. Tempered glass

Low iron tempered suede glass (also known as white glass) has a transmittance of more than 93% for the solar cell spectral response (in the wavelength range 320-1100 nm) and has a high reflectivity for infrared light greater than 1200 nm.

This glass is also resistant to solar ultraviolet radiation and its transmittance is not reduced.

The glass must be clean and free from water vapor. The two surfaces of the glass should not come into contact with bare hands. It usually has functions such as supporting the structure of photovoltaic modules, improving the load-bearing and durability of photovoltaic modules, transparency, anti-reflex transparency, water resistance, gas resistance and anti-corrosion.

3. EVA packaging adhesive film

It is a hot melt adhesive, a copolymer of ethylene and vinyl acetate. It is used to encapsulate solar cells, prevent the external environment from affecting the electrical performance of solar cells, increase the transparency of photovoltaic modules, and bond solar cells, tempered glass and backplanes together, and has a certain adhesion strength.

It also has a gain effect on the electrical performance output of the photovoltaic module.

4. Photovoltaic welding strip

Also known as tinned copper strip, it is basically divided into interconnection strip and bar strip. Interconnecting strips are used in the connection between solar cells, acting to conduct electricity and collect current from the solar cells.

The bar strip is used to connect the solar cell arrays of the components, combining the current generated by the solar cells and transferring it to the junction box.

5. Solar cells

Solar cells are devices that convert direct light energy into electrical energy. They are made of semiconductor materials. By illuminating with sunlight, electron-holes pairs are excited and the dissociation of electron-holes pairs is realized using the electrostatic field in the P-N bonding region.

The separated electrons and holes are collected outside through the electrode and form a current.

6. Back panel

The backshield is used as the packaging material, the most common types include TPX, KPX and PET, and improves the aging and corrosion resistance of photovoltaic modules and prolongs the service life; the white backplane improves the light absorption efficiency of the PV module by diffusing the light entering into the PV module.

It also has high infrared emissivity, so it can reduce the operating temperature of the PV module; it also improves the insulation performance of photovoltaic modules.

7. Connection box

It is a box installed on photovoltaic modules, which has the function of current conduction and has good electrical performance. At the same time, the design and size of the junction box should meet the requirements of the use environment, such as electrical, mechanical, heat resistance, corrosion resistance and weather resistance. At the same time, it should not cause harm to users and the environment.